Corrosion-resistant chains

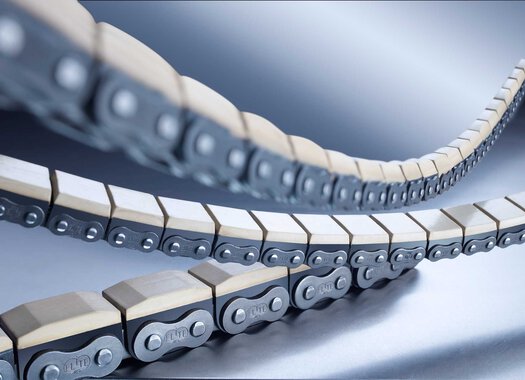

Corrosive environments require chains with high fatigue strength and wear resistance. Chains made from normal steel grades corrode quickly, so corrosion-resistant chains are used in such applications. A wide variety of coatings and material combinations can guarantee that a chain is corrosion-resistant. Our product range includes roller chains made from rustproof material (CF stainless steel, CF b.dry), available in nickel-plated or galvanised CR versions. Chains with zinc-aluminium coating (ZAP) are a new addition to the range. However challenging your application, we are confident we can supply the right chain.

Categories that may be of interest to you

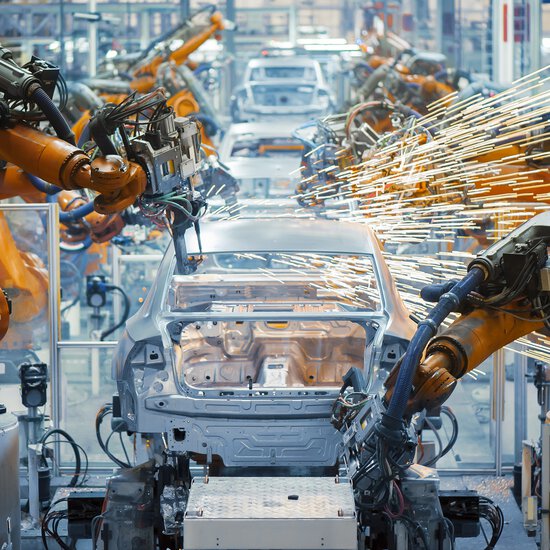

Our diversity for your applications

Four main factors have an impact on chain corrosion: the medium or environment in which the chain operates, the chain material, machinery or plant design, and the duration and type of application. These main parameters help to define the right chain for a given application.

Corrosion-resistant chains with alternative coatings are also available on request. For example, iwis meets special customer requirements by combining different coatings to achieve high wear resistance while guaranteeing a high level of corrosion protection for attachments.

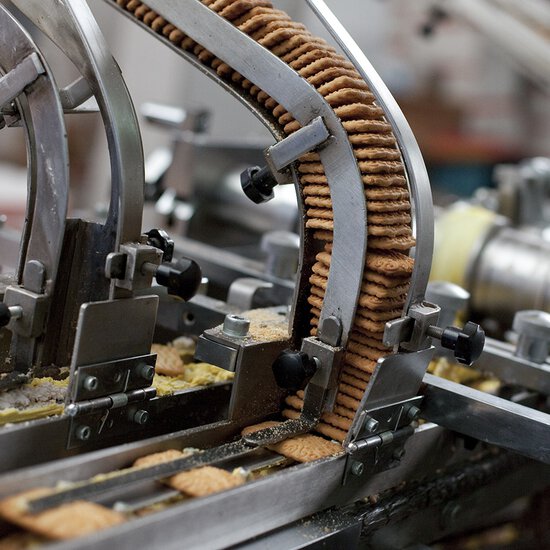

Stainless steel chains are used mainly in food production or in applications where frequent chain cleaning is required. iwis supplies stainless steel chains made from materials that ensure they can be used in acidic or alkaline environments. Versions with bent attachments, special attachments and extended pins are also available.

CR chains are corrosion-resistant, made from hardened, highly alloyed steel grades, and have significantly higher tensile and fatigue strength than ordinary rustproof (stainless steel) chains. CR chains are used in all applications that require chains to remain flexible despite corrosive environments, or to remain rust-free for hygienic or visual reasons.