Plate chains

iwis plate chains ensure the safe, smooth conveying and accumulation of workpiece carriers and workpieces. Their design allows extremely tight curve radii, which enables a much more economical use of space than other conveyor systems. JWIS brand plate chains feature special plates that are pressed directly onto the chain pins. This guarantees an absolutely flat, step-free transport track in the tightest of spaces. The base chain is also completely covered, which prevents both injury to operating staff and damage to the conveyed goods.

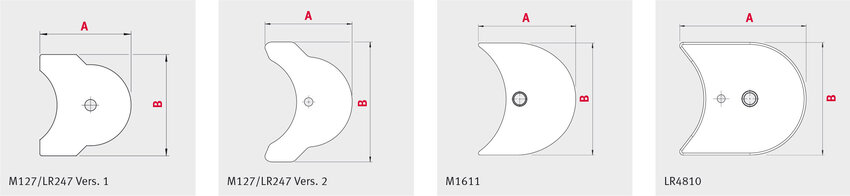

Some examples of plate chain versions

iwis offers a wide range of plate forms and two plate material alternatives for the individual configuration of your conveyor system.

Engineering

On request, iwis will design customer-specific solutions for conveyor systems. Our design engineers will provide support with the configuration, calculation and development of new conveyors.

Contact us for more details!

Highlights

- Wide variety of different plate shapes allows individualised conveyor system design

- Various alternative plate materials available

- The iwis plate chain program includes roller chains according to standard ISO 606 (DIN 8187), ISO 1275 (DIN 8181) as well as works standard

- Guarantees an absolutely flat, step-free transport track

- Low noise emission

- Effective protection of functional areas of the chain

- Intermeshing design of plates provides a continuous flat surface for workpiece transport

- Special plate shape allows the construction of very tight bends

- Long conveying distances possible in very small spaces

- No risk of injury

- DIN sprockets may be used

- CAD data of all plate chain types available

Further technical information can be found in our Plate chain product flyer.

Categories that may be of interest to you

Low-noise accumulation and conveying

iwis plate chains guarantee an absolutely flat, step-free transport track, even in the narrowest spaces. Special plate shapes and materials ensure safe, smooth transport and accumulation of articles such as workpieces or workpiece carriers around the tightest bends, so optimum conveyor tracks are possible in restricted spaces. DIN standard sprockets can be used for these applications, and roller chains in accordance with ISO 606, ISO 1275 or factory standard are possible.

Plate chains are mainly used in general conveyor technology, tool transport, the automotive industry, in under-floor conveyors and applications that require conveying and buffering.