Sprockets

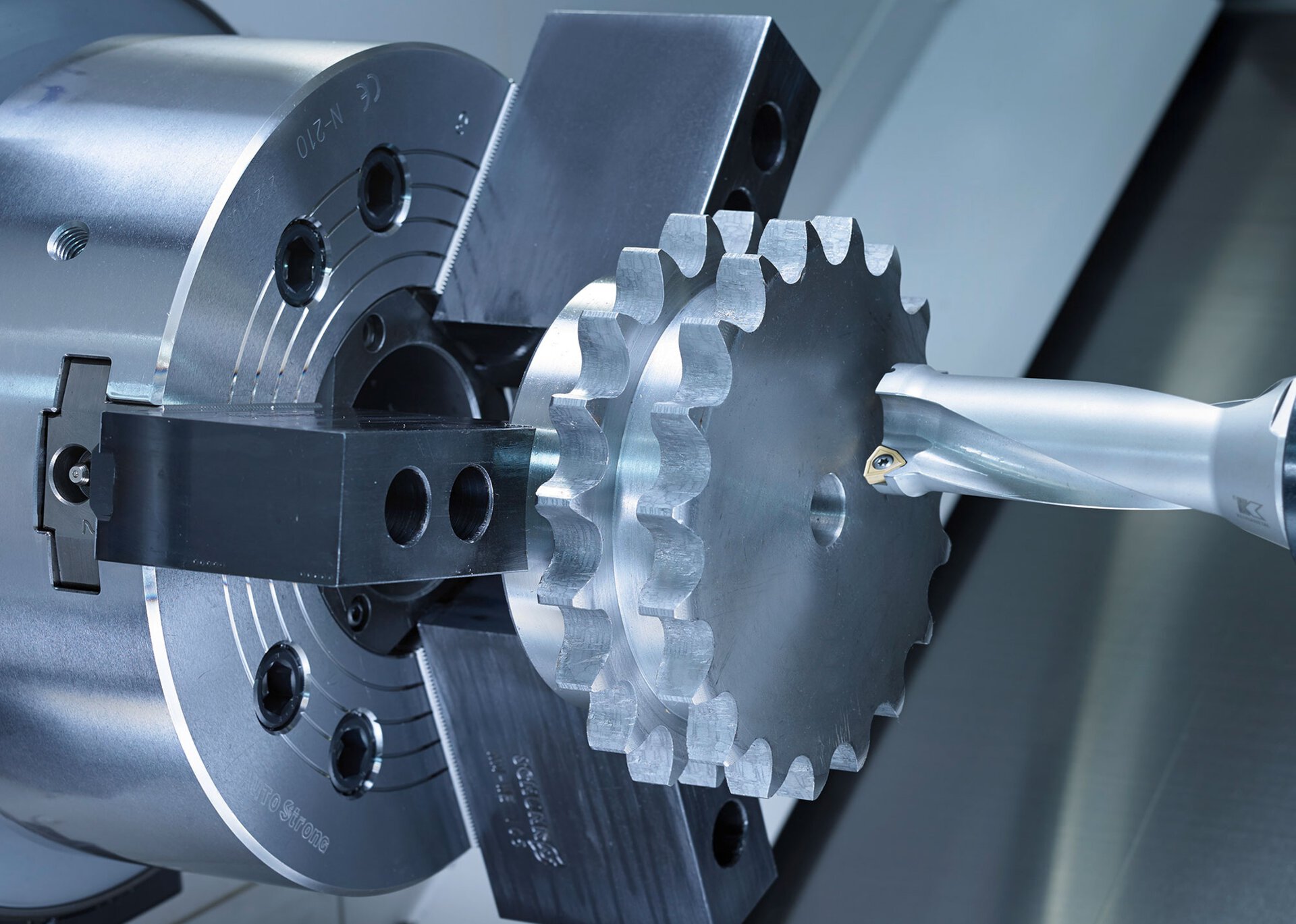

Our new sprocket manufacturing machinery enables iwis to combine the latest production processes with tried and tested methods to realise customer orders individually, quickly, reliably and to high quality standards.

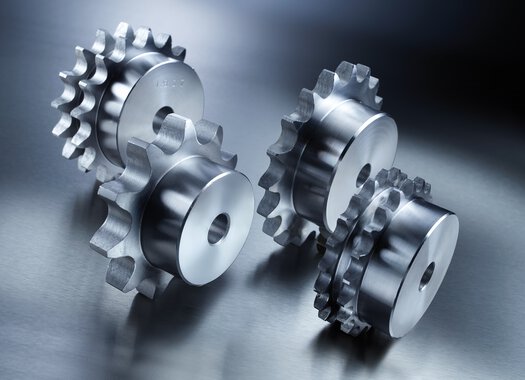

iwis manufactures sprockets, plate wheels to DIN standards, and special sprockets made in accordance with your specifications, drawings or samples. iwis always keeps a wide range of ISO 606-compliant standard sprockets (sizes 04B-1 to 32B-3) in stock for immediate delivery.

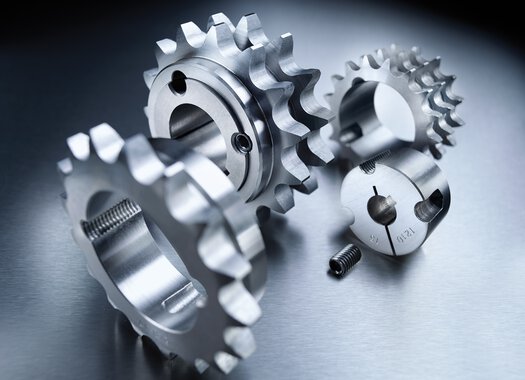

Sprockets with taper-lock bushes

Taper-lock clamping bushes enable the precise axially-centred fixing of hubs on shafts. When used with sprockets, they offer the advantage of faster fitting and better centring than with a shaft-to-hub connection with keyways.

Sprockets and plate wheels

Our drive systems division iwis antriebssysteme can supply a wide range of sprockets and other related drive components from stock, including standard sprockets and ISO 606-compliant plate wheels with pilot bores.

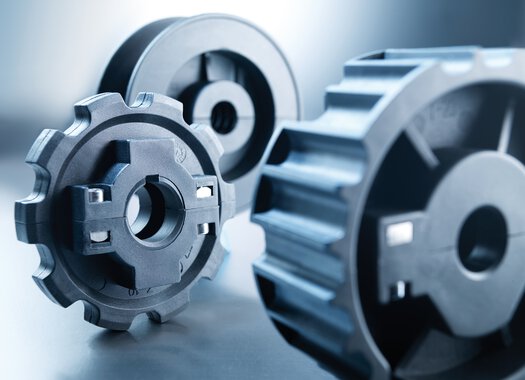

Sprockets for flat top chains

Our flat top chain product range includes a wide variety of sprockets and idler wheels. Single-piece and split sprocket versions are available. Choice of materials for idler wheels: plastic PA6, cast iron or steel ST52.

Chain tensioners with ball bearings

All chain tensioning wheels are supplied as a set with fitted ball bearings. The bearings are sealed on both sides and lubricated for life, so they are maintenance-free.

If you require special sprockets manufactured in accordance with your specifications, drawings or samples, please use our Configurator or contact our Customer Service department.

Go to sprocket and plate wheel Configurator

It is also worth taking a look at our range of drive components, which includes more torque transmission systems such as automatic chain tensioners, tensioning box, torque limiters, torque limiters with chain coupling and conventional chain couplings.

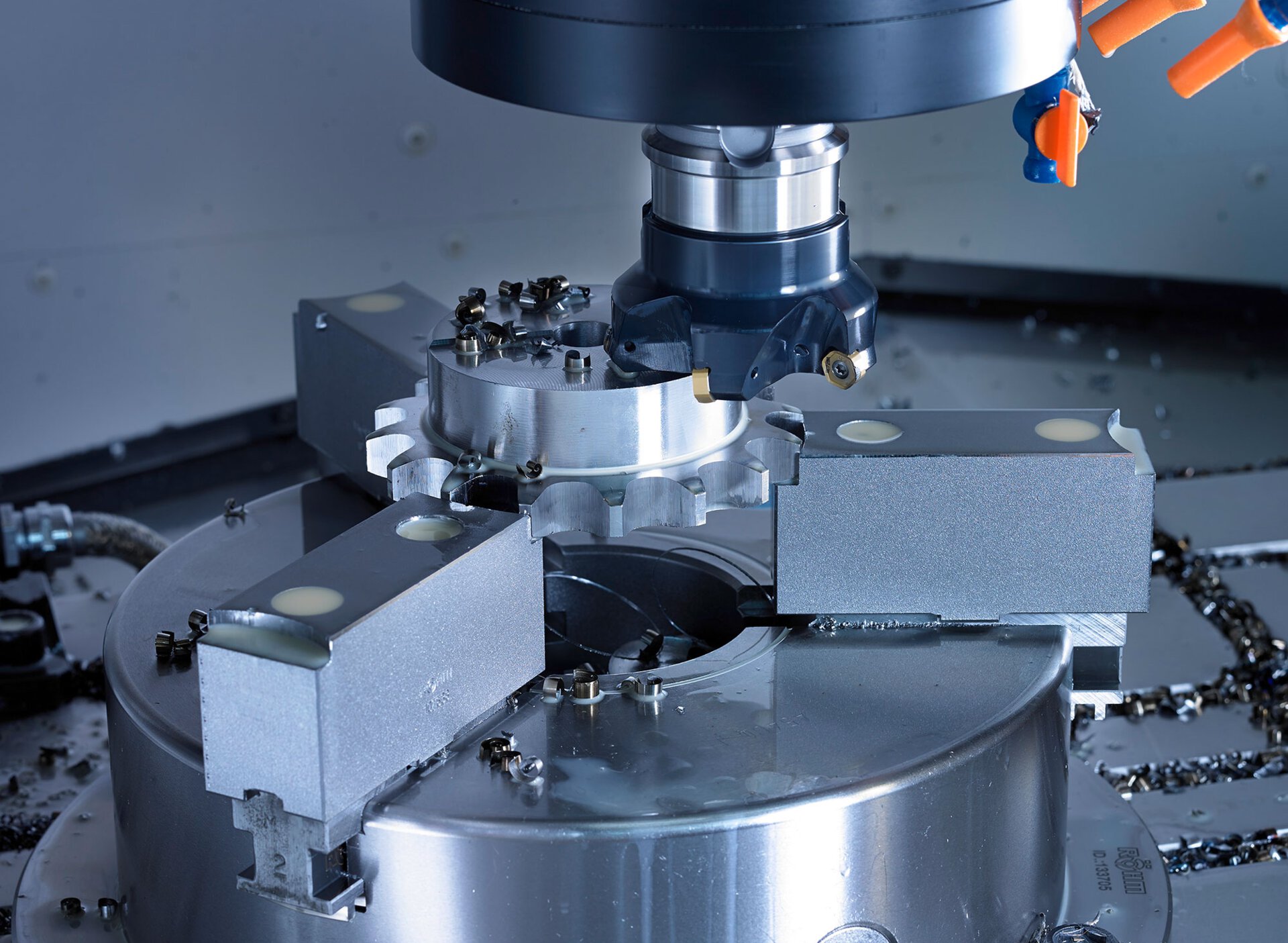

iwis sprocket production – as individual as your drive

It has always been our aim to realise your product requirements individually, rapidly and reliably. The new sprocket manufacturing machinery at our Wilnsdorf site raises the bar even higher: by combining the latest cutting-edge production processes with tried and tested methods, we are now in a position to complete your orders quickly and to your complete satisfaction. Shorter lead times are only one of the many benefits the new machinery offers. An additional advantage is that in-house manufacturing of sprockets and plate wheels enables customer-oriented production of these components according to your specifications, drawings or samples. Our preferred materials are heat-treated alloyed and unalloyed steel, but other special materials can also be processed for you on request.

Diverse range of sprocket versions

- Keyways in accordance with DIN 6885/1 from keyway width 3 P9/JS9 – 25 P9/JS9, various special sizes available on request

- Conventional internal machining of sprockets and turned parts with a max. external diameter up to 620 mm and a max. turning length up to 500 mm

- Push-fit insertion of bearings into components as per drawing; manufacturing of chain tensioning sprockets on specially equipped hydraulic presses

- Inductive heat treatment of tooth geometry to prolong service life of the materials also possible at customer request

- Surface treatment such as galvanising, black oxidation or nickel-plating available

- Sprockets with high tolerance requirements

- Pitch hole and threaded bore drilling

- Production of machine-processed parts of any shape or size up to 350 mm diameter or max. dimensions of 1,050 mm x 560 mm x 460 mm