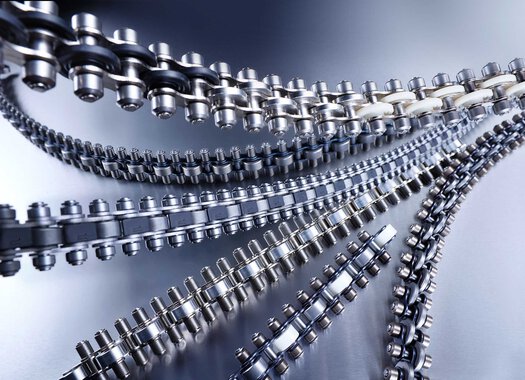

Transfer chains

Open conveyor systems are susceptible to contamination by foreign bodies or small parts, which can cause belt malfunction or damage the transported goods. iwis transfer chains for conveyor systems prevent such costly malfunctions before they can occur. Transfer (TF) chains are completely enclosed on three sides by wear-resistant, rugged snap-on plastic attachments, even when they pass over the sprockets. The close-fitting attachments completely cover the functional areas of the chain, effectively eliminating the risk of injuries to staff and possible damage to machine-processed workpieces with sensitive surfaces, for example.

Corrosion resistance / maintenance-free operation

Corrosion-proof CR chains, nickel-plated chains or low-maintenance MEGAlife chains with maximum service life can also be used as base chains for transfer chains. For more information on these chains, please refer to the catalogue “JWIS Precision chain systems for drive and conveyor purposes”.

Attachment characteristics

iwis offers three attachment versions. The basic assumption for all temperature specifications is a max. surface pressure of 0.45 MPa; significantly higher temperature ranges are possible if surface pressure is lower. Please contact iwis in advance for advice.

Different material configurations are possible for special applications e.g. with gradients, accumulation or aggressive media. In these cases, please contact iwis for an individual advisory consultation.

Find out more about the different attachment versions made of extremely hard-wearing materials:

- Standard applications

- Heat-resistant applications

- Antistatic applications

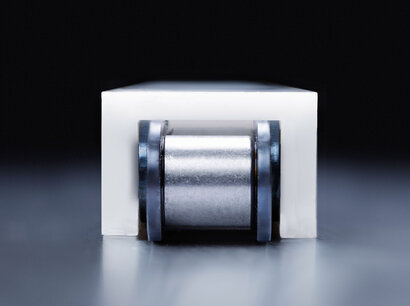

Connecting link

The chain ends are connected by a two-pin outer link block and a push-fit side plate pressed onto the pins. By bending the chain appropriately, the two attachments can be clipped on over the pin. A locking spring is not required. The two relevant attachments are coloured black for easy location of the connecting link.

Highlights

- All-round protection of functional components of the chain: attachments enclose the chain on three sides, even in the vicinity of sprockets

- Variety of base chains available e.g. MEGAlife, nickel-plated or corrosion-proof

- Gentle handling of delicate goods

- Close-fitting covers prevent the risk of injuries and malfunctions

- Outside of the chain is absolutely clean, so there is no accumulation of dust

- Drive chain always remains clean, even under adverse operating conditions

- Suitable for horizontal and vertical installation

- No lifting of the load in the vicinity of the sprockets

Further technical information can be found in our Transfer chain product flyer.

Categories that may be of interest to you

Transfer chains from iwis: gentle, strong and versatile

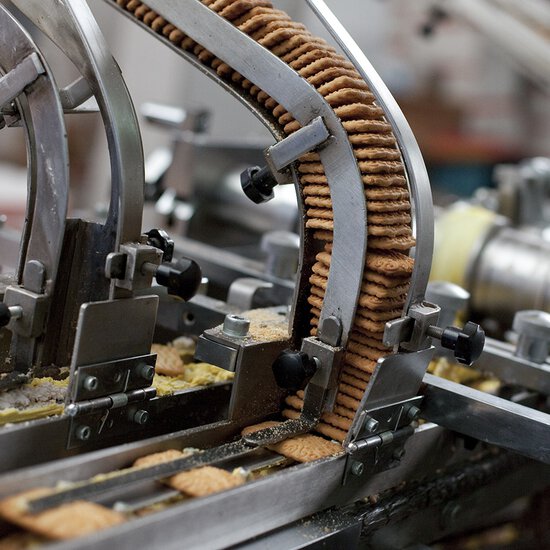

iwis transfer chains are suitable for conveying, handling and synchronising containers and workpiece carriers, particularly in applications where gentle handling of sensitive items is required. Some typical application fields are the food processing industry, electronic components and PCB production, medical devices and pharmaceuticals, and glass and pottery processing.

Information on other technical parameters such as resistance to chemicals or other attachment versions (e.g. wear-resistant, high temperature-resistant etc.) is available on request. DIN 8187 standard sprockets can be used for transfer chains. Provided that sprockets with z > 18 are used, the TF chain remains completely enclosed even where it passes over sprockets, and the base chain is protected against the ingress of foreign bodies.