Premium Solution MEGAlife

Our maintenance-free iwis chains

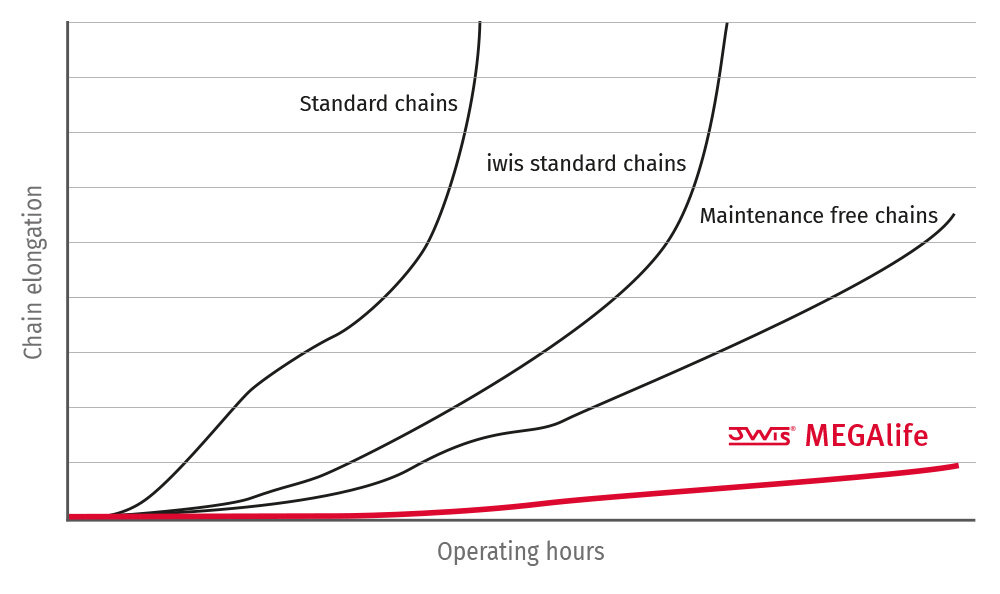

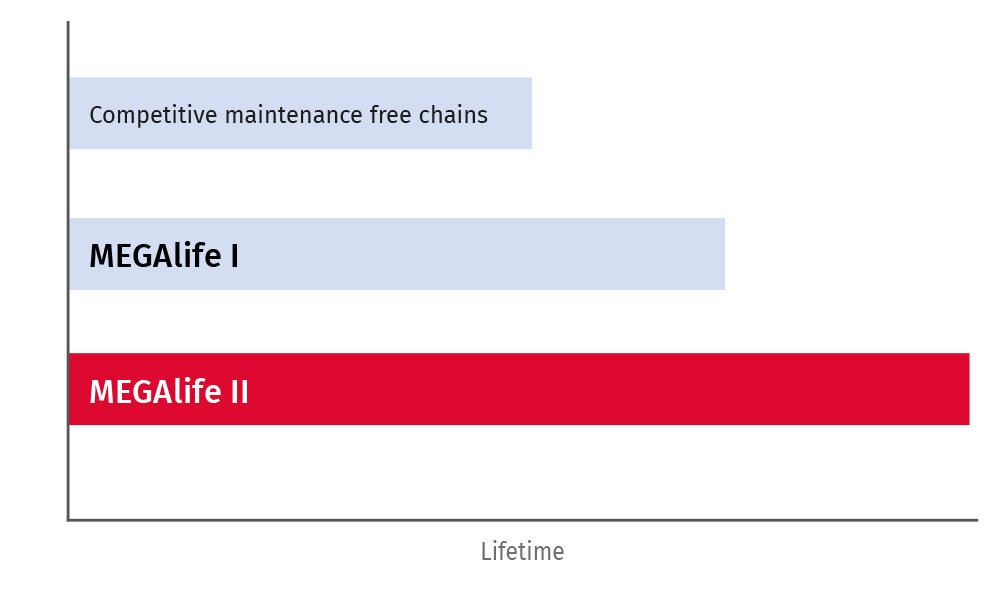

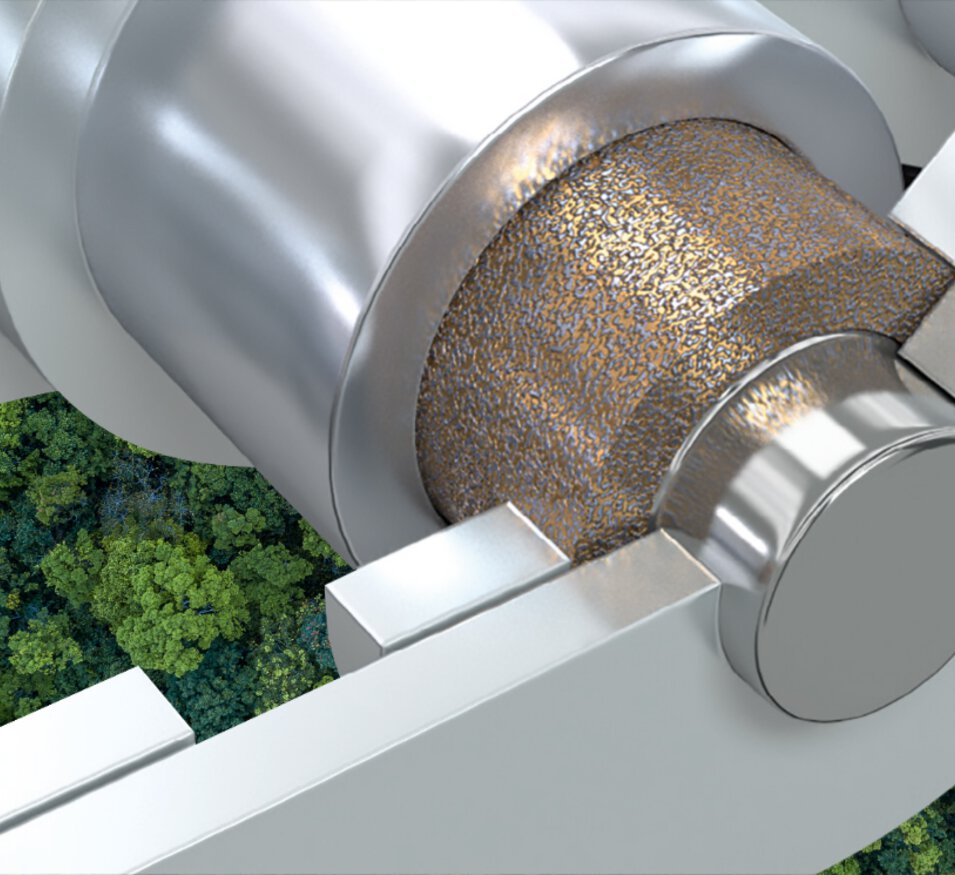

The best possible wear resistance and low maintenance requirements are crucial criteria for the performance of drive and conveyor chains. With the maintenance-free MEGAlife chains from iwis, we offer a premium solution that leads the industry in terms of quality.

MEGAlife maintenance-free roller and conveyor chains convince with high quality and performance and are also sustainable. Thanks to their high precision and load capacity, they are the first choice for numerous demanding applications.

MEGAlife Highlights

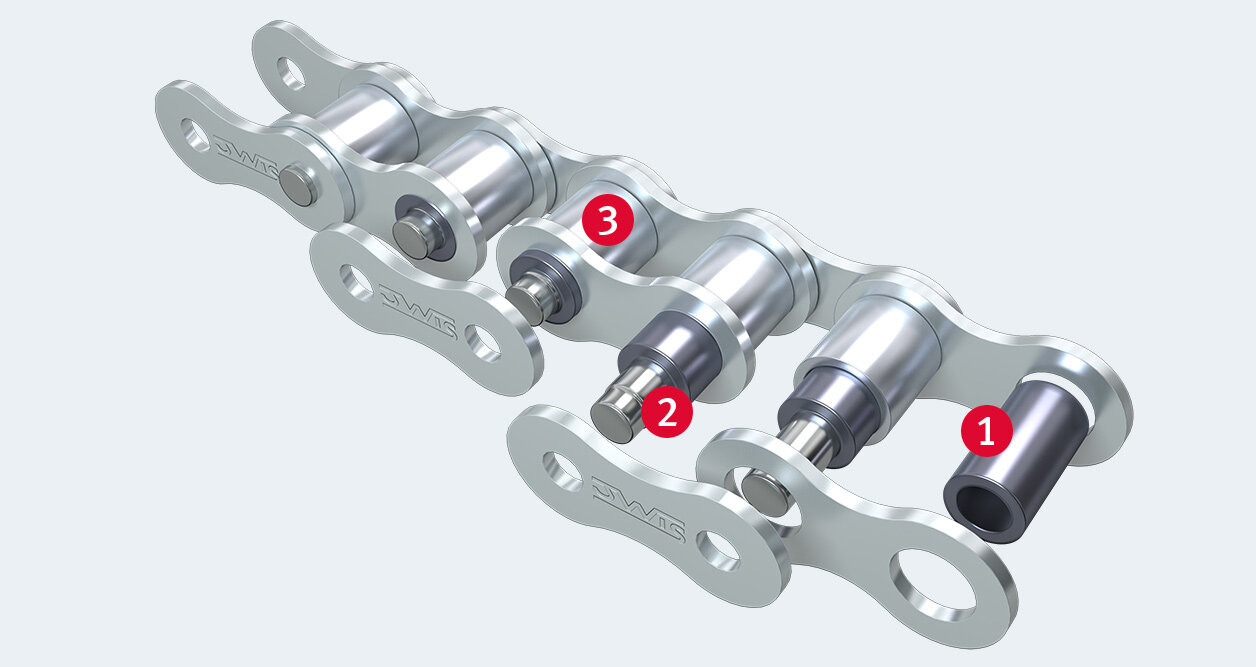

- Oil-impregnated high-performance sintered bushes

- Pins with corrosion-resistant, friction optimized coating

- Seamless rollers with corrosion-resistant coating and optimized geometry

Trial without re-lubrication at high speeds.

Graphic representation corresponds to iwis test results.