UNIPRESS – setting new standards in press-fit technology

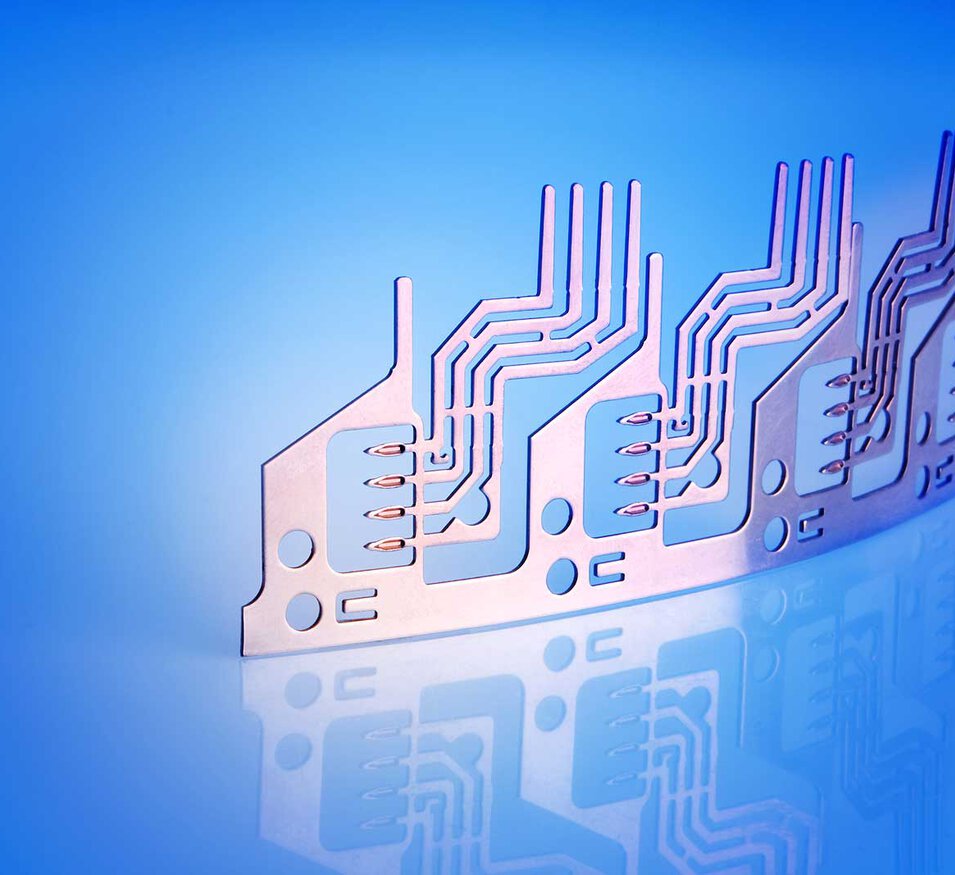

UNIPRESS sets new standards, underlining a high level of innovative strength which offers direct benefits to our customers. Many years of experience, millions of stamped products and outstanding toolmaking expertise enable us to realise contacting technology products with unrivalled technical characteristics.

There is no doubt that press-fit technology will replace conventional soldering technology in the foreseeable future. In press-fit technology, a press-fit pin is inserted into the through-hole plating of a PCB, with subsequent elastic deformation of the pin. The diagonal cross-section of the pin is then larger than the hole in the PCB, which produces a solder-free, gastight, corrosion-proof electrical connection.

Technical highlights:

- Fulfil the requirements of DIN / IEC 60352-5 and various application specifications

- Tested by an independent, impartial laboratory

- Various elastic zone geometries available

- For PCB drill holes from 0.8 mm to 1.6 mm

- Operating temperature ranges up to 125 °C and 150 °C

- Highly conductive, durable, easy to handle

- Production as punched strips or pins on tape reel

- Special selectively galvanised surfaces to prevent formation of chips and whiskers

- Combinations with other connection technologies (crimp/spring contact punched grid, IDC technology etc.) available

- Integration in sub-assemblies

Applications in the following industries:

- Automotive

- Manufacturing

- Electronics

- Communications

Your contact at iwis smart connect:

Marc-Michael Enzensperger, Head of Sales

Tel: +49 8362 9122-0