Custom Hybrid Attachments Plates

New hybrid production possibility lowers the cost of special designs and reduces waiting times for attachment plates

Your challenge:

Manufacturing custom attachment plates using conventional methods represents a serious challenge for developers of new ranges of machines: Long delivery times as a result of operations such as bending, punching or laser erosion, high unit prices for small runs and restricted plate geometries are everyday problems in the development process.

Our solution:

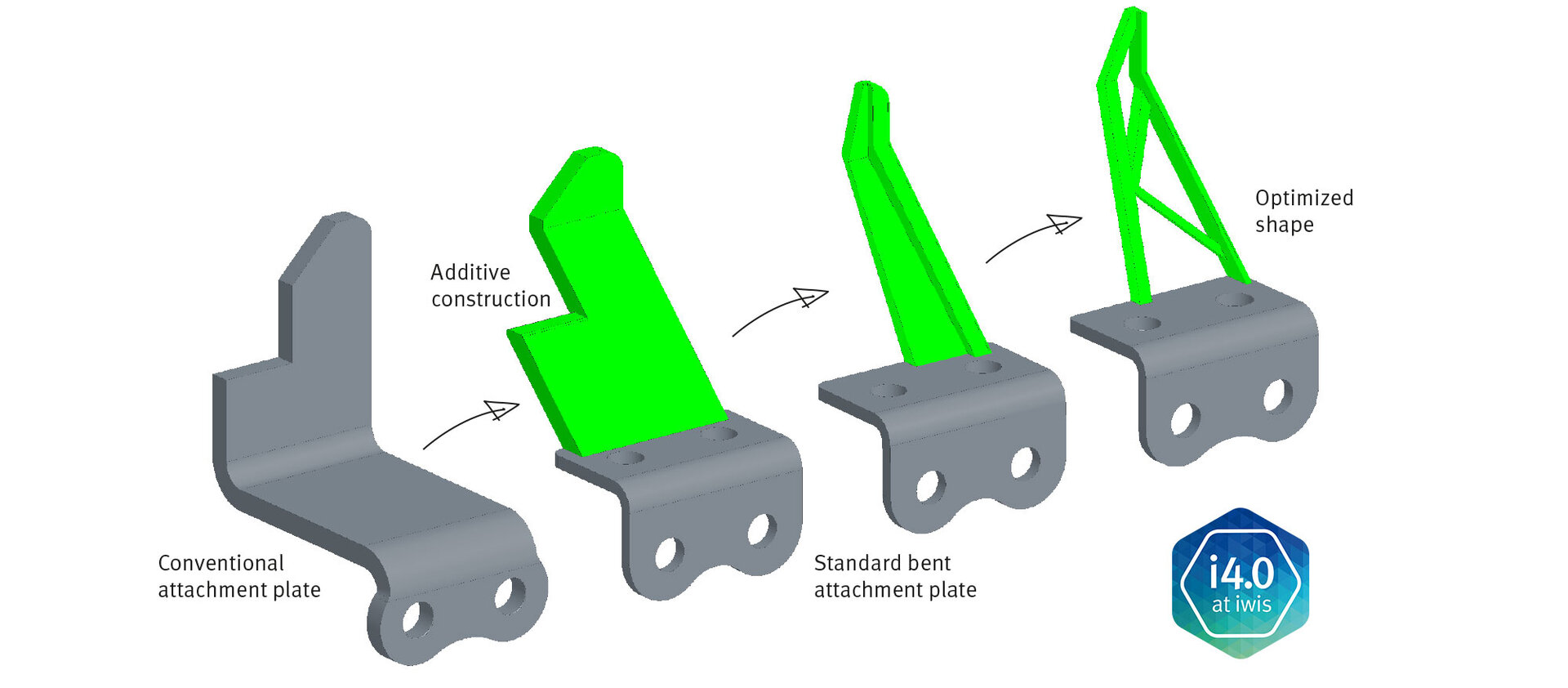

The new direct hybrid manufacturing technology (DHM) offers you the best from two different manufacturing technologies. Combine the benefits of conventional manufacturing technology with the possibilities offered by additive manufacturing and give your partners greater flexibility in development.

The fusion of these two technologies opens up a wide range of new possibilities for machine manufacturers: You can develop new plate geometries that are precisely tailored to meet an individual requirement without making any compromises in respect of quality and precision.

Value added for you

Unrestricted shaping

- No limitations compared with conventional manufacturing processes

- New possibilities for the design of custom shapes and shapes optimized for specific applications

Cost-effectiveness

- Short delivery times

- Batch sizes as of 1 can be manufactured

- Considerable increase in energy efficiency by reduced material consumption

- No tooling costs for different attachments

Selection of materials

- A range of coating options

- Steel

- Stainless steel

- Aluminium

Maximum Flexibility

DHM brings together conventional production of a standard component and custom enhancements as required by the customer: During hybrid manufacturing of attachment plates for JWIS roller chains with attachments, we use an additive process that offers you many benefits. These include unrestricted shaping for the development of new ranges of machines, low unit costs for short runs and fast delivery times for your custom-made products.

And another plus:

The new attachment plates are considerably lighter, despite their high strength, and thus improve the energy efficiency of your systems. A bonus for sustainability and the environment.

The DHM process involves taking a standard plate and supplementing it with a tailored plate design from the customer using an additive/generative process. This involves depositing layer upon layer of metal powder on an existing standard bent attachment plate until the required shape is achieved. The completed assembly can then also be finished and coated to give the required surface quality and corrosion resistance.

Another environmental consideration

Unlike other processes, such as mechanical machining, the additive process produces virtually no waste in the powder bed, as more than 97 % of the powder is re-used.