Top performance right from the start

In day-to-day operation, drive chains in operation are subjected to constant mixed friction, high surface pressure and, under certain circumstances, mechanical shocks. Aggressive environmental conditions and extreme temperatures often put chains under even more stress. Adequate and effective lubrication of chain links increases the service life of the entire chain many times over.

Selecting the right lubricant and appropriate lubrication method for the job guarantees satisfactory wear reduction, adequate corrosion protection and optimum damping characteristics. Countless tests on purpose-built apparatus and close collaboration with leading lubricant manufacturers have established iwis as the expert partner in all aspects of chain lubrication.

The right iwis initial lubricant for every application!

Careful selection of a suitable lubricant for the application in question is decisive for orderly running-in elongation and a long chain service life.

Not only the lubricant itself, but also the manner in which it is applied are crucial for subsequent chain performance.

Useful information

The following aspects are crucial when choosing an initial lubricant:

- Temperatures in the application

- Contamination (type and quantity)

- Moisture

- Substances that may come into contact with the chain

- Frequency and method of cleaning

- Compatibility with the relubricant

- Drive chain speeds

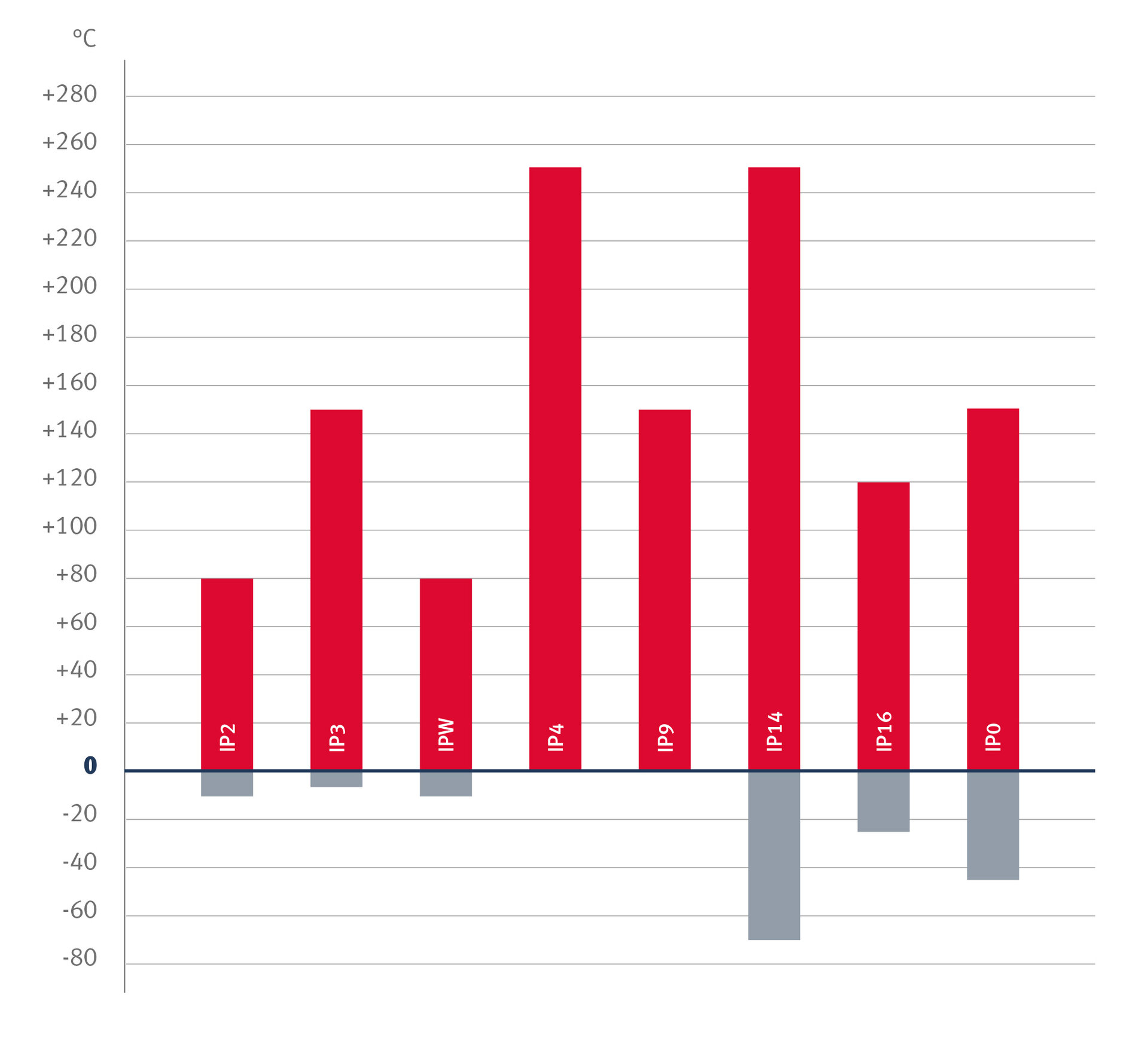

JWIS brand initial lubricants

IP2

Standard lubricant with good lubricating properties and outstanding corrosion resistance for all applications.

IP3

Long-term lubricant for high-speed applications, absolutely non-drip and non-splash.

IPW

High-performance lubricating wax with good adhesion; very high wear protection permits significantly longer relubrication intervals. Unproblematic use in all environments where dust and powder are present.

IP4

Thermally stable high-temperature lubricant that provides good protection against wear and corrosion.

IP9

Corrosion protection for preservation with minimal lubricating effect.

IP14

Dry lubricant for slow-running chain drives and low to medium loads.

IP16

Food-grade lubricant with good wear and corrosion resistance. Meets the stringent requirements of USDA‑H1 and LMBG.

IP0

Low-temperature lubricant with optimum lubricating effect. Free-flowing across entire temperature range.

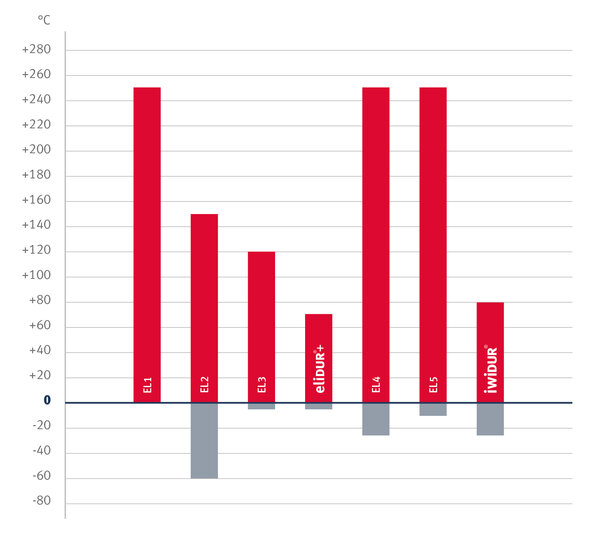

ELITE brand initial lubricants

EL1

High-performance lubricant for operating temperatures up to 250°C.

EL2

FDA H1-rated food-grade lubricant.

EL3

Long-term, mineral oil-based lubricant with special additives to improve adhesion and corrosion protection.

ELIDUR+

Lubrication and corrosion protection, specially designed for use on roller chains.

EL4

Synthetic high-temperature lubricant with an extremely wide temperature range.

EL5

Synthetic Teflon high-temperature lubricant with long-term effect.

iwiDUR

New generation of food-grade wax lubricant with FDA-H1 classification.

Proper relubrication is just as important as initial lubrication for prolonging chain service life. You can find more information about relubrication here.

Please do not hesitate to contact iwis directly if you have any questions or need further advice on initial lubrication and relubrication.