Chain solutions for the confectionery industry

Chains and chain drive systems used in confectionery production, one of the most important branches of the food industry, must meet extreme requirements. The crucial factors are steady, reliable parallel running, precise positioning and optimised downtimes to guarantee maximum efficiency and trouble-free conveying of moulds. Cleaning, relubrication and corresponding product safety are also becoming increasingly important issues.

Thanks to the wide and diverse range of suitable products, products, processes, materials and lubricants we provide, iwis precision chains offer outstanding service life, the highest possible length accuracy and narrow tolerances for pair-matched chains in every application.

Positioning / Accuracy

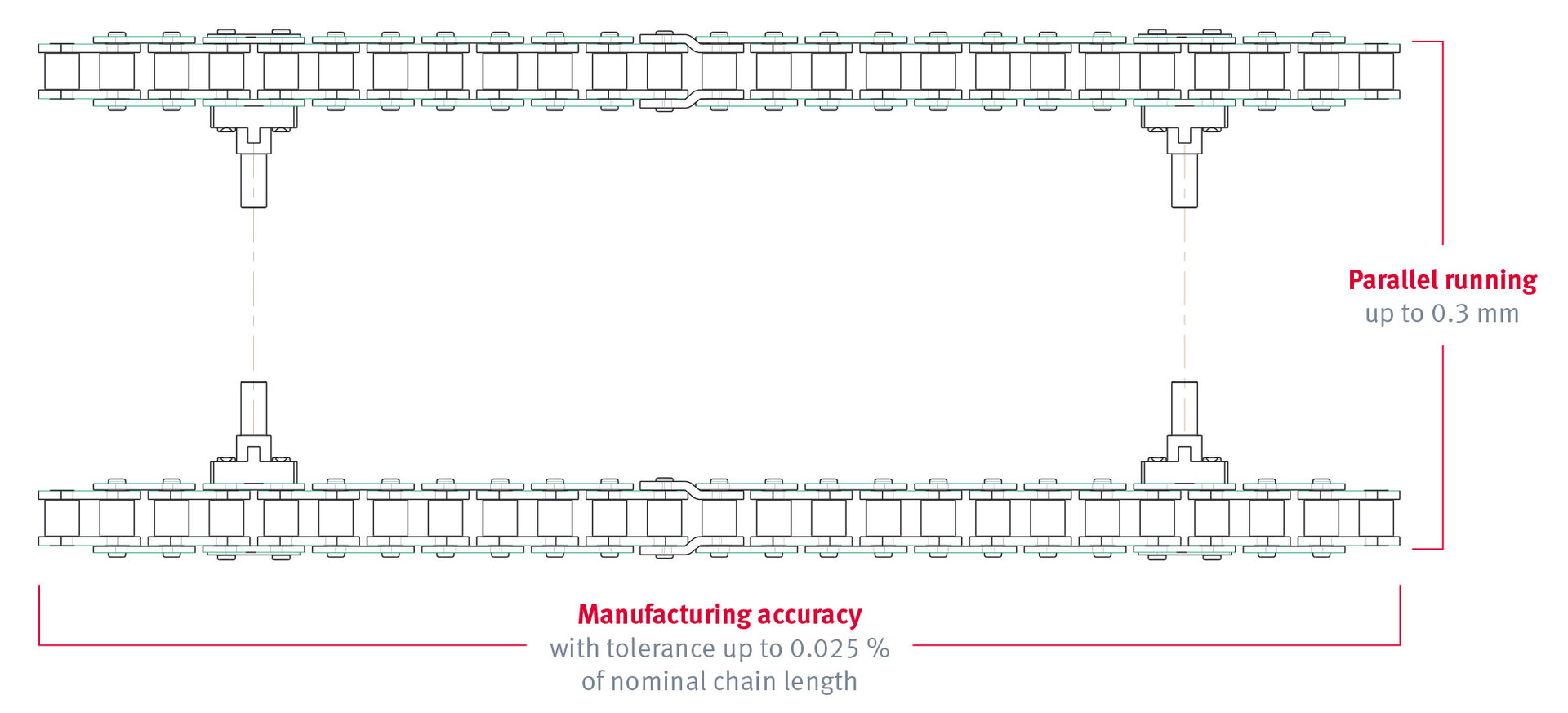

Applications in the confectionery industry often involve the conveying of finished products or moulds, which in turn requires the use of roller chains with restricted length tolerances to guarantee high-precision parallel drives and accurate relative positioning of chain attachments.

Chains manufactured to standard DIN ISO 606 must be produced to tolerances between +0 to +0.15 % of their nominal length under a defined measuring force and length. In the case of a 5-metre standard length chain, this can mean length deviations of up to 7.5 mm.

Thanks to a special production process, we are able to reduce the tolerance range of our JWIS precision chains even further – as little as 0.025 % of the nominal length – thereby achieving maximum possible accuracy within individual roller chains.

With parallel drives consisting of two chain strands, parallel running to within 0.3 mm– regardless of total chain length – can also be achieved, which guarantees accurate positioning.

Your iwis contact for the confectionery industry:

Markus Glorius

Phone. +49 151 40243745

Chains for confectionery industry applications:

MEGAlife maintenance-free

MEGAlife is synonymous with maintenance-free roller and conveyor chains. Just two typical reasons for using a maintenance-free chain are when access to automotive industry conveyor systems for maintenance work is difficult, or when relubrication is inconvenient or undesirable. MEGAlife roller chains combine excellent wear protection and durability with corrosion protection and eco-friendliness.

b.dry Maintenance-free stainless steel chains

Stainless steel chains also belong to the “maintenance-free” category. They are extremely wear-resistant, rustproof and absolutely dry. The secret of b.dry chains is their special construction: they are made from rustproof, maintenance-free CF stainless steel with an optimised bearing design, in combination with a b.dry bush.