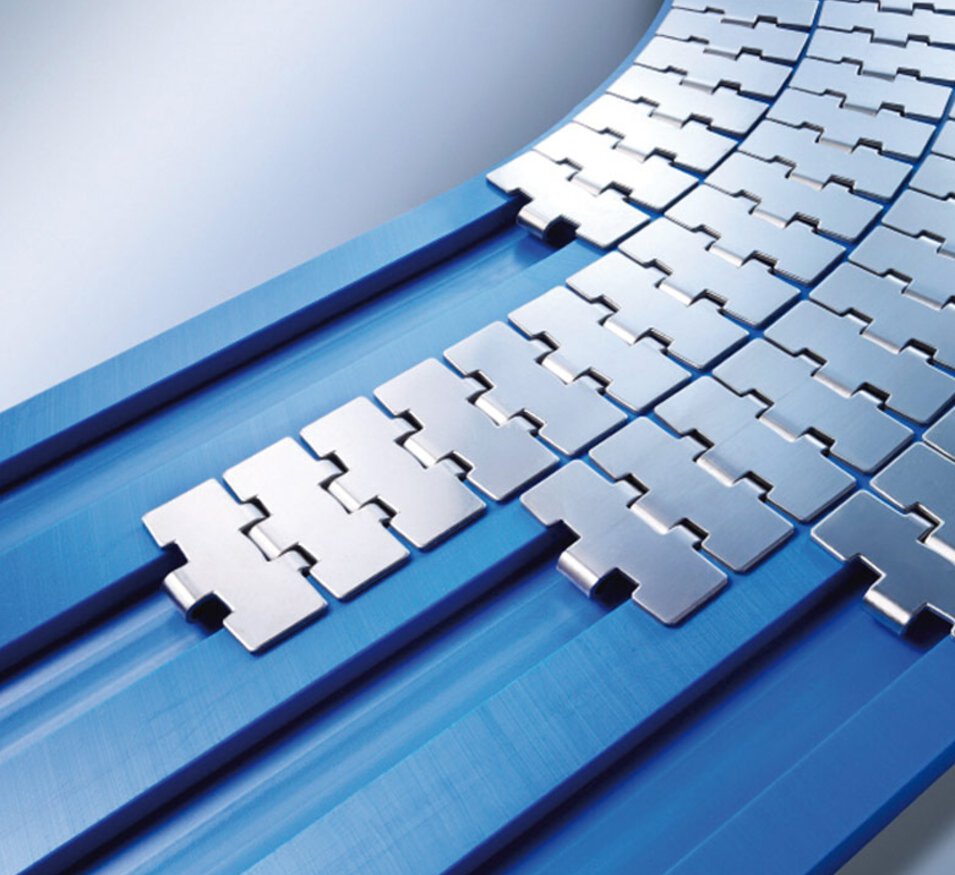

Magnetic corner tracks

Pulsation-free running and evenly balanced tensile and retaining forces on all tracks are necessary for gentle, low-noise conveying of products in the food, beverage and packaging industries.

Magnetic corner tracks are single- or multi-track plastic guides for flat top chains. Flat top chain pins are attracted by pairs of magnets to hold the chain in the bend. When the pins pass from one magnetic field to the next, the chain sticks very briefly before moving on. This phenomenon is called pulsation, or stick-slip. This pulsation effect can be so pronounced that vibration is transmitted to the goods being conveyed, which can even cause them to fall over in extreme cases.

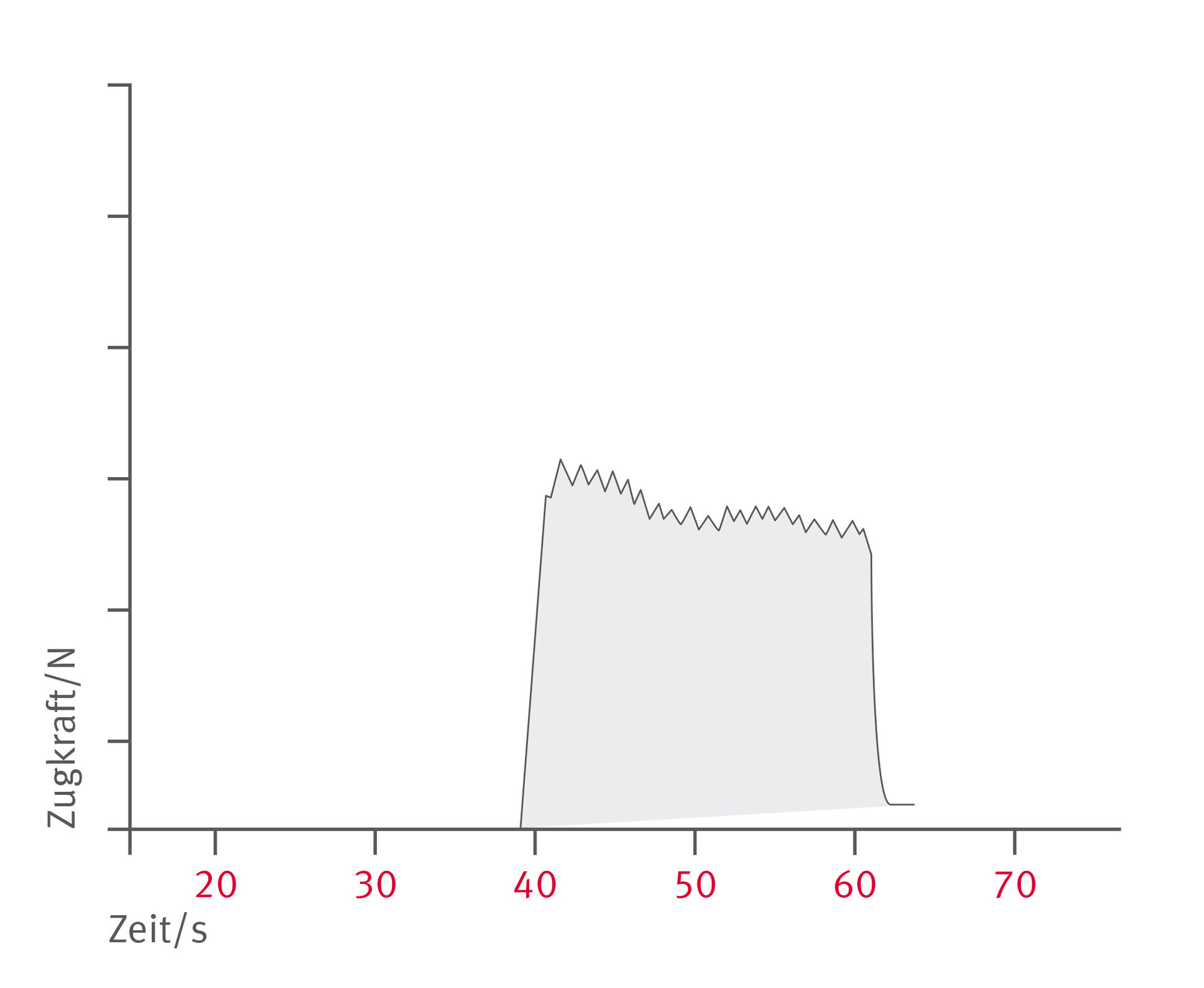

Optimisation of the magnet arrays, adjustment of the strength of the magnetic fields and increased field sizes mean that the stick-slip effect has been reduced to practically zero in the new FLEXON magnetic corner tracks.

Products can now be conveyed gently without jolts or excessive noise.

Reduced tensile forces in bends

It was possible to reduce tensile forces occurring in bends by up to 60 per cent. As a result, the new magnetic corner tracks reduce drive power consumption and allow longer conveyors to be constructed without increasing drive performance, thus enabling energy savings. The ingenious track-specific arrangement of the magnets depending on pin diameter and chain pitch ensures that FLEXON magnetic corner tracks achieve virtually identical tensile and retention forces in every track.

As the tracks have outstanding sliding properties, flat top chains are less susceptible to wear. The tracks are made from high-quality, durable materials for long service life. FLEXON magnetic corner tracks are available in all standard sizes for all common flat top chains, radii and angles. The range also includes standard TAB and bevel curves. iwis can also manufacture magnetic corner tracks in accordance with individual customer drawings.

Benefits of FLEXON magnetic corner tracks

Less force required

=

longer conveyor lines possible

=

fewer transfer stations required

=

fewer potential risk areas

Less force required

=

reduced chain wear

=

reduced track wear

=

reduced drive power

=

increased energy saving potential

=

lower costs

Magnetic corners tracks put to the test

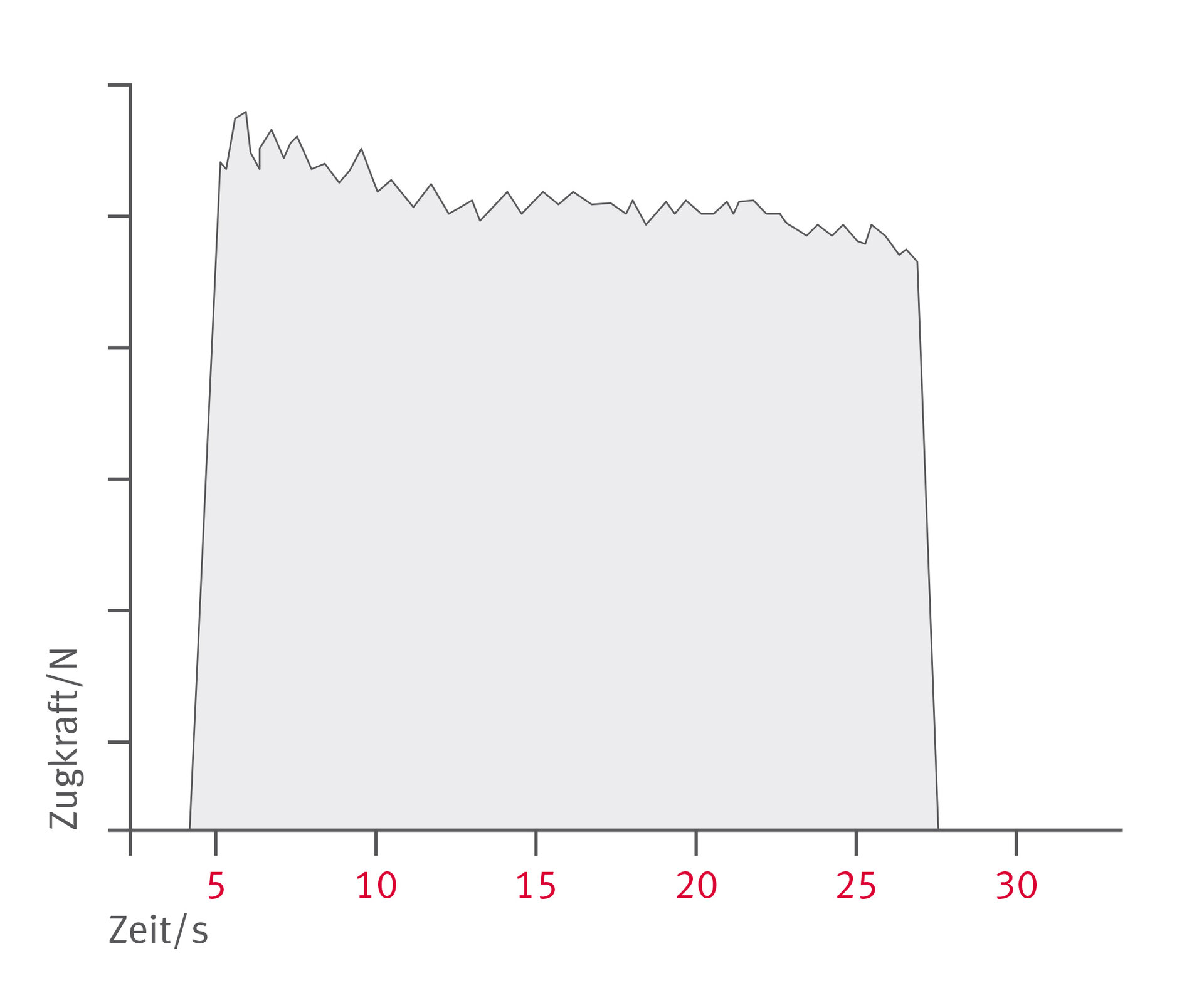

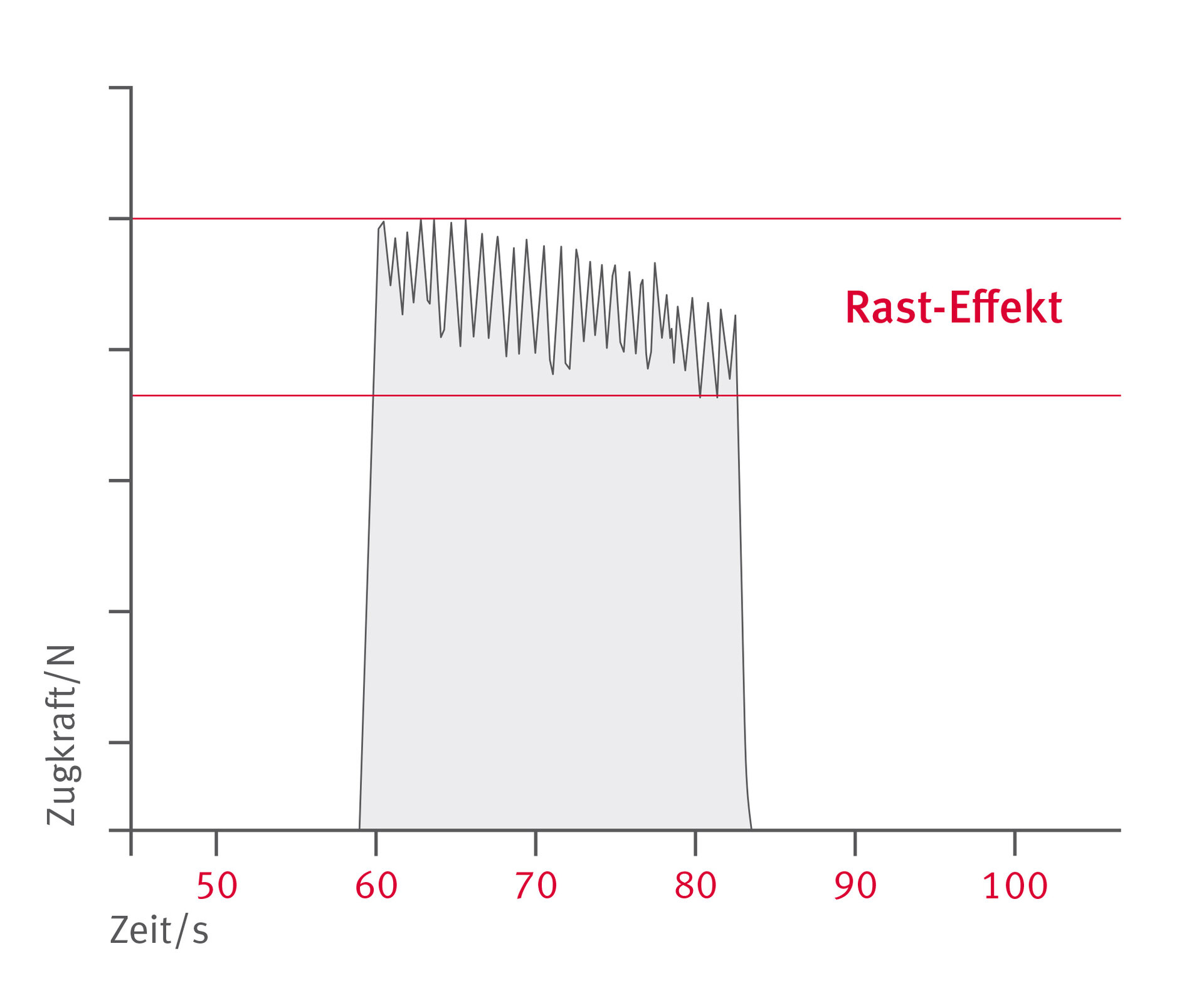

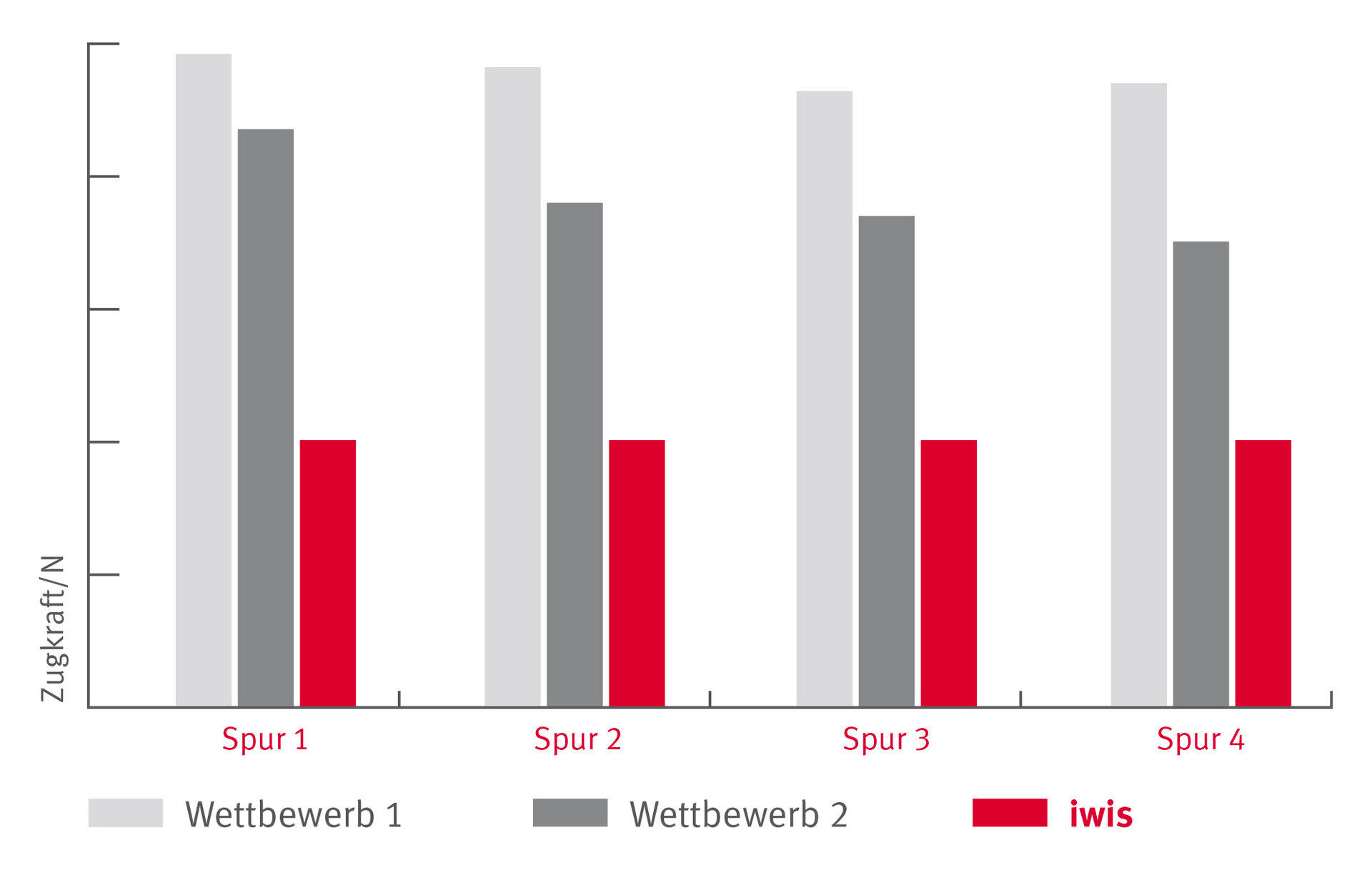

In our laboratory we tested magnetic corner tracks from well-known manufacturers for retaining force, slip-stick, and required tensile force in the curve. All tests were carried out on four-track curved sections.

competitor 1: track 2

competitor 2: track2

iwis FLEXON-magnetic corner tracks: track 2

Test results

Our tests showed that FLEXON magnetic corner tracks exhibit the lowest pulsation.whereas the results for competitors’ curves showed varying tensile and retaining forces in the respective tracks. On all our competitors’ curves, the forces decreased as the length of the track increased. By contrast, with the new FLEXON magnetic corner tracks the tensile and retaining forces remained virtually constant in all four tracks.

This innovation is patented by FLEXON.

How does iwis achieve pulsation-free operation with the new FLEXON magnetic corner tracks?

- Optimisation of magnet arrangement

- Adaptation of the magnetic field strength

- Increased size of magnetic fields

How do FLEXON magnetic corner tracks achieve constant tensile and retention forces in every track?

- Arrangement of magnets by length in relation to the curved track

Comparison of force required in the individual tracks

The measurements for the respective individual tracks were compared across all the curves tested. The example of Track 2 clearly illustrates the difference between the various makes of curve.

While results for the competitors’ curves show that the greatest force is required in Track 1, the least force is in Track 4.

The FLEXON magnetic corner track from iwis displays a constant value across all tracks.

What is pulsation, or the stick-slip effect, in magnetic corner tracks?

Pulsation, otherwise known as the stick-slip effect, occurs when a flat top chain is pulled around a magnetic corner track. Flat top chain pins are attracted by pairs of magnets to hold the chain in the bend.

When the pins pass from one magnetic field to the next, the chain sticks very briefly in the track before moving on. This phenomenon is called pulsation, or stick-slip. This effect can be so pronounced that vibration is transmitted to the goods being conveyed, which can create problems with the conveyor or even cause the goods to fall over.

Product range

The FLEXON magnetic corner track range includes not only all standard sizes for all common flat top chains, radii and angles, but also TAB and bevel curves. Do you need magnetic curves manufactured according to your individual specifications? We will be glad to help with the design and then produce them for you.