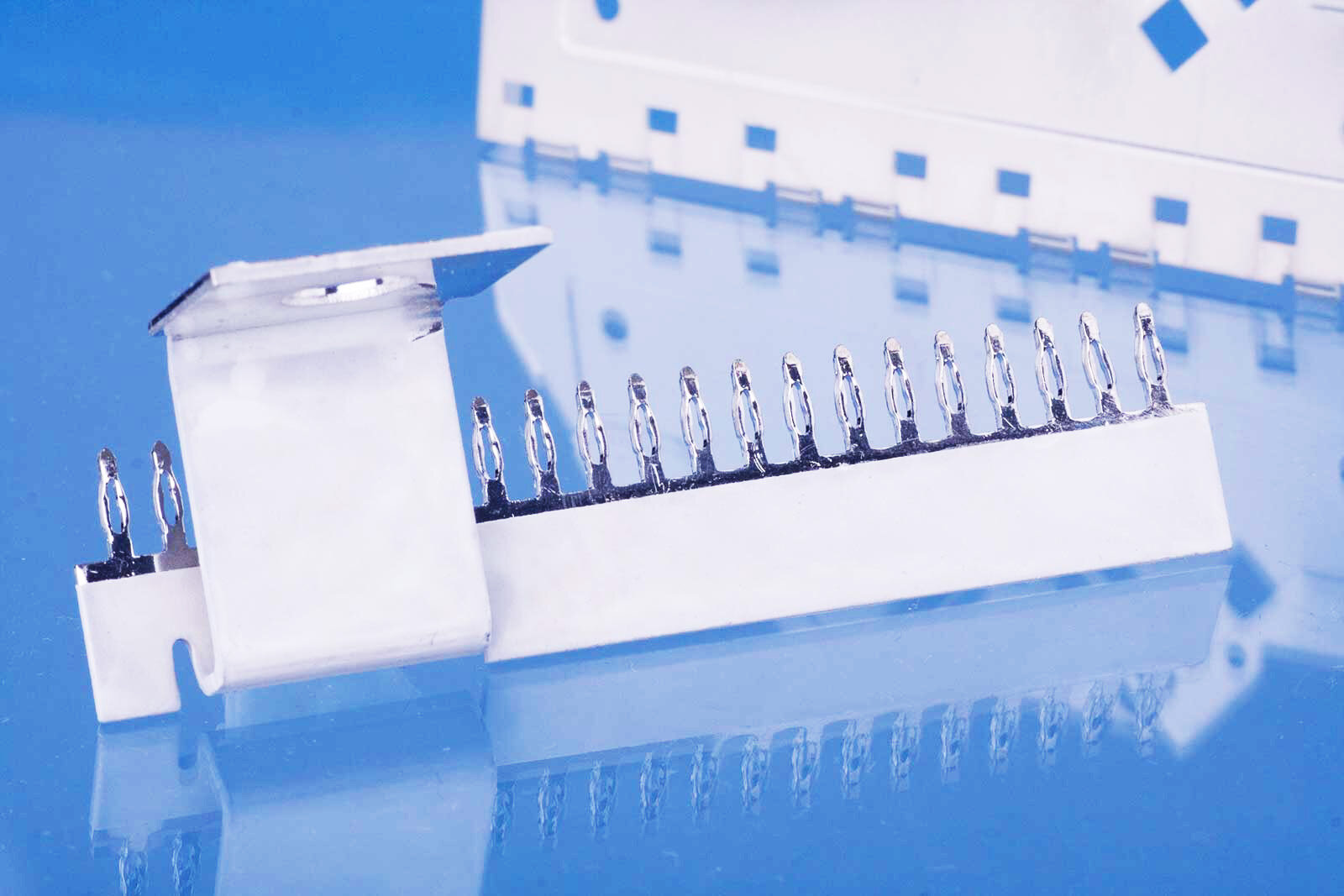

Stamped/bent parts

The product portfolio is as broad and diverse as the market segments in which smart connect products are used: our high-precision stamped / bent sheet-metal parts perform vital functions in the following fields:

Automotive, aerospace, electronics, IT and communication technology, control and sensor technology, and apparatus, plant and mechanical engineering.

Precision for every product development stage

Our products

Installation frames and housings, contacts and springs, connectors and fixing elements, busbars, high-frequency/EMC shielding technology and chain plates.

Development

Our customers define the task – we deliver the solutions. We always keep serial production in mind when assessing feasibility. Our engineers design and develop the product in close cooperation and ongoing dialogue with the customer. They also create operating instructions, test schedules and test reports.

Toolmaking

Our own toolmaking department designs and manufactures soft tools, auxiliary tools and complex progressive tools up to a length of 1,800 mm. Highly qualified staff maintain, service and repair all tools. Change requests can always be implemented in the ongoing manufacturing process.

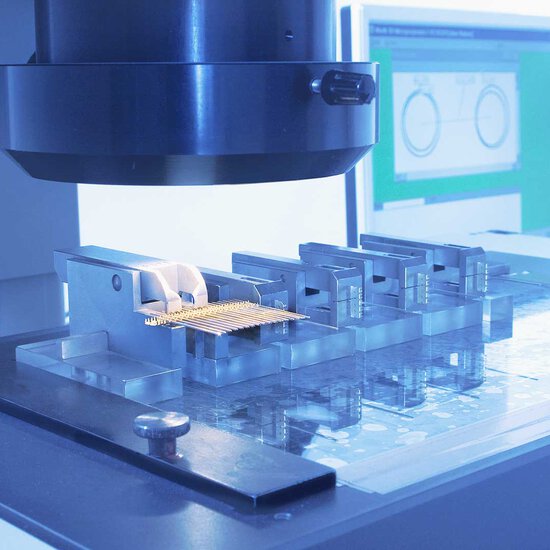

Pilot series and small series production

State-of-the-art CNC stamping machines and laser machines enable the performance of multiple processing steps during a single clamping process. Edgers, grinders and deburring machines are available for subsequent processing operations. This manufacturing mode is ideal for the flexible production of small and medium-sized quantities.

Serial production

Our diverse range of automatic stamping machines with press forces from 25 t to 250 t is capable of handling different grades of steel, carbon steel, stainless steel, aluminium and non-ferrous metal alloys in thicknesses from 0.15 to 4 mm. Our experienced workforce produces high-precision punched, bent and drawn parts on these machines.

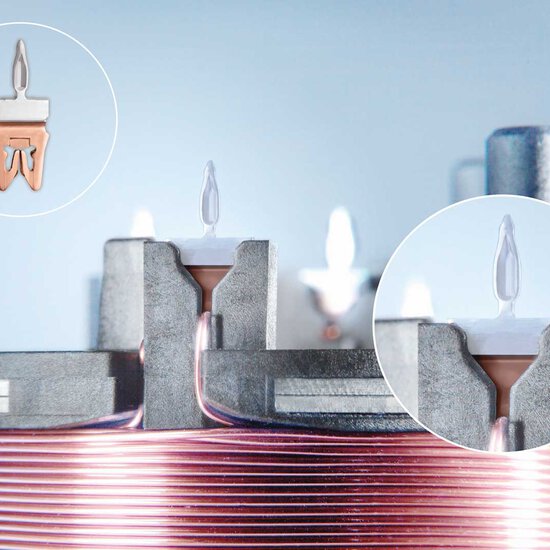

Stamped and bent parts

- High-speed stamping up to 2000 strokes/min

- Material thicknesses from 0.01 to 2.0 mm

- Punched from strips, taped or loose

- Mechanically joined or welded

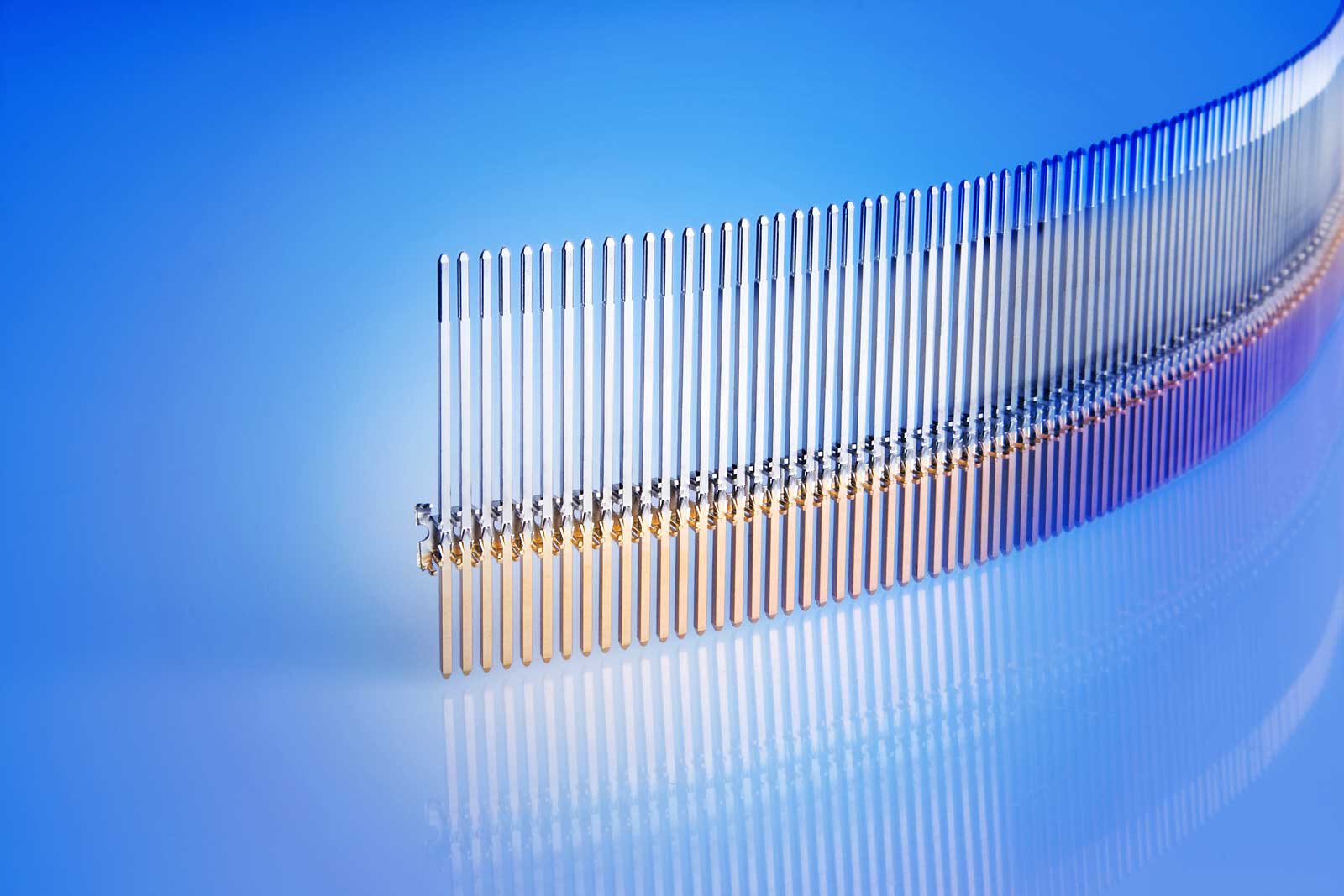

Wire nails

- Various geometric forms, round or square

- Reel stock or loose

- Various reel stock versions

- Embossed or cut points

- Customer-specific lengths and Raster

- Untreated, pre-treated or selectively galvanised versions

- Straight or curved forms

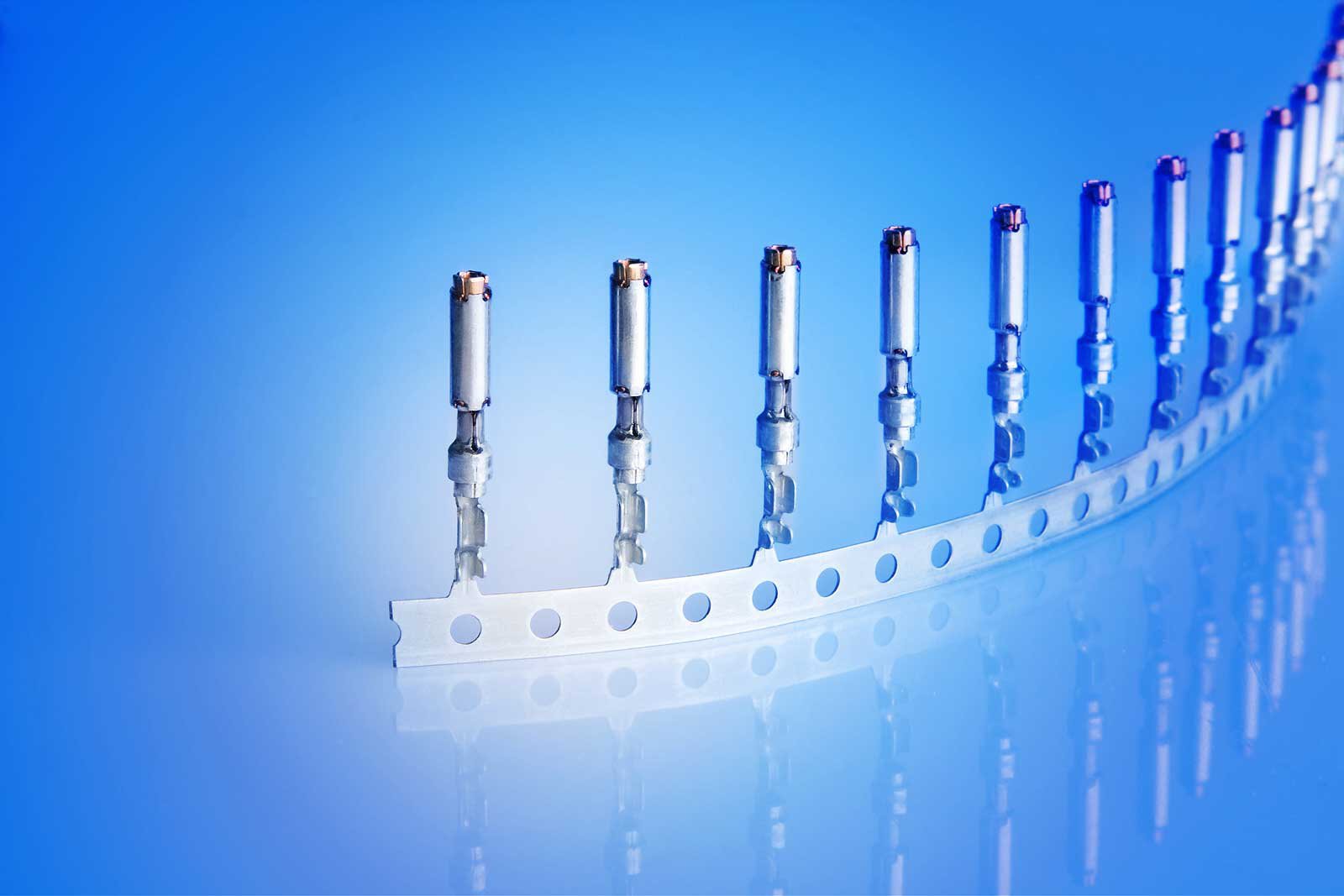

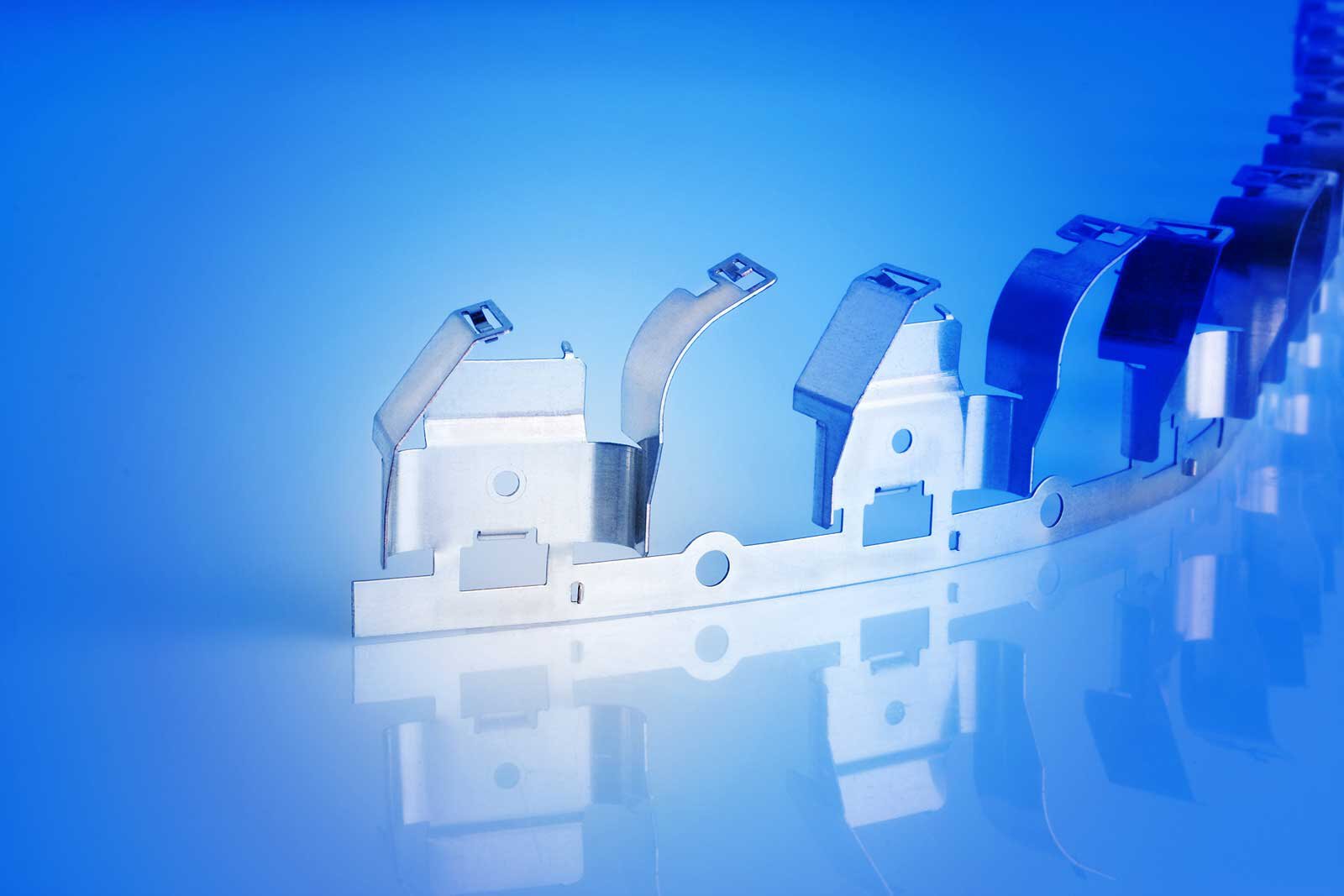

Multi-part contacts

- Single- or multi-phase production

- Welded or mechanically locked versions

- Separate outer cage or inner plate

- Male contacts with soldered pins

- Variety of material combinations with copper alloy and stainless steel available

- Various surface coatings

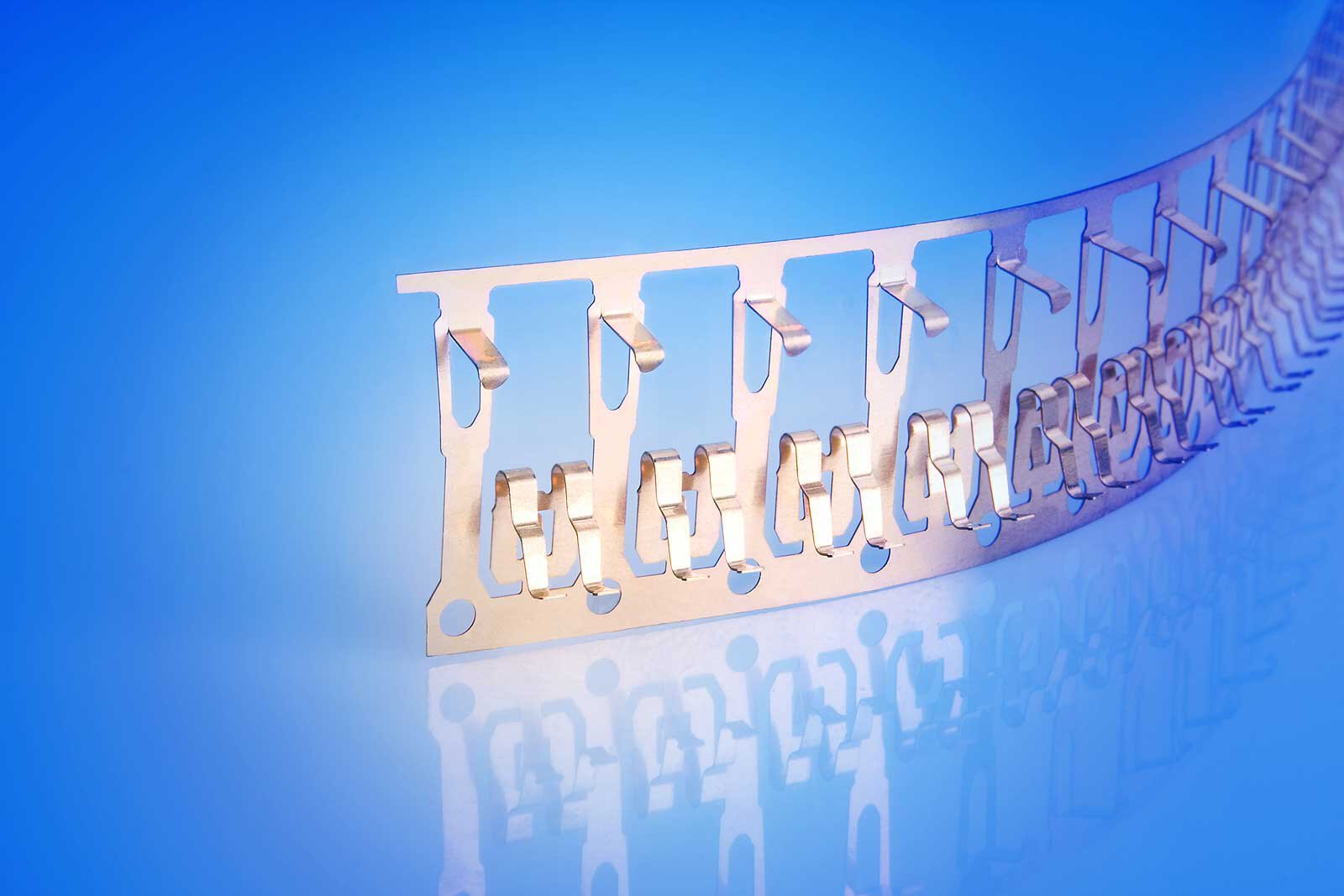

Springs and clips

- One-piece and complex bent forms

- Reel stock or loose

- Various base materials

- Selectively or fully galvanised surface

- With and without subsequent heat treatment

- Secure, damage-proof packaging

Shields & housings

- EMI / EMV protection

- Mechanical protection

- Complex customer-specific versions

- Integrated mounting elements

- Single- or multi-part solutions

- Various materials (steel or copper alloys) and surfaces available

Flat connectors

- Simple and complex geometries

- Various pin tip forms

- Single repeat-pattern parts or stamping grid

- Push-fit and soldered versions / combinations

- Integrated latching elements

- Connection for automatic processing

- Various surface combinations available

- Overmoulding or push-fit versions

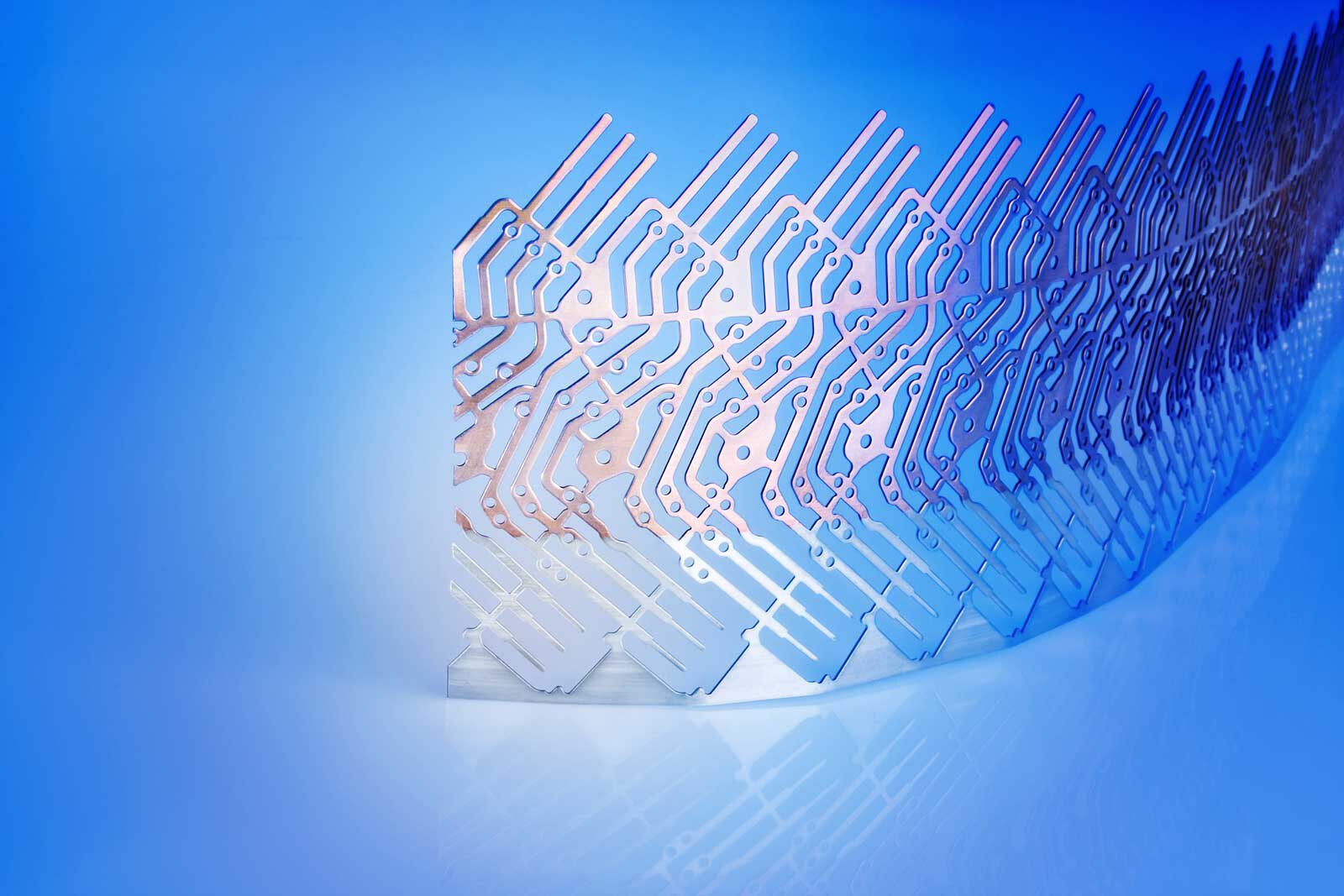

Stamping grids

- Layout according to application specification

- Integrated connector /plug-in geometries

- Flat or pre-formed designs

- Blank / pre-treated or selectively galvanised

- Reel stock or single items

- Punch-out separators for further processing

- Suitable for overmoulding or automatic assembly

- Various materials available, depending on application

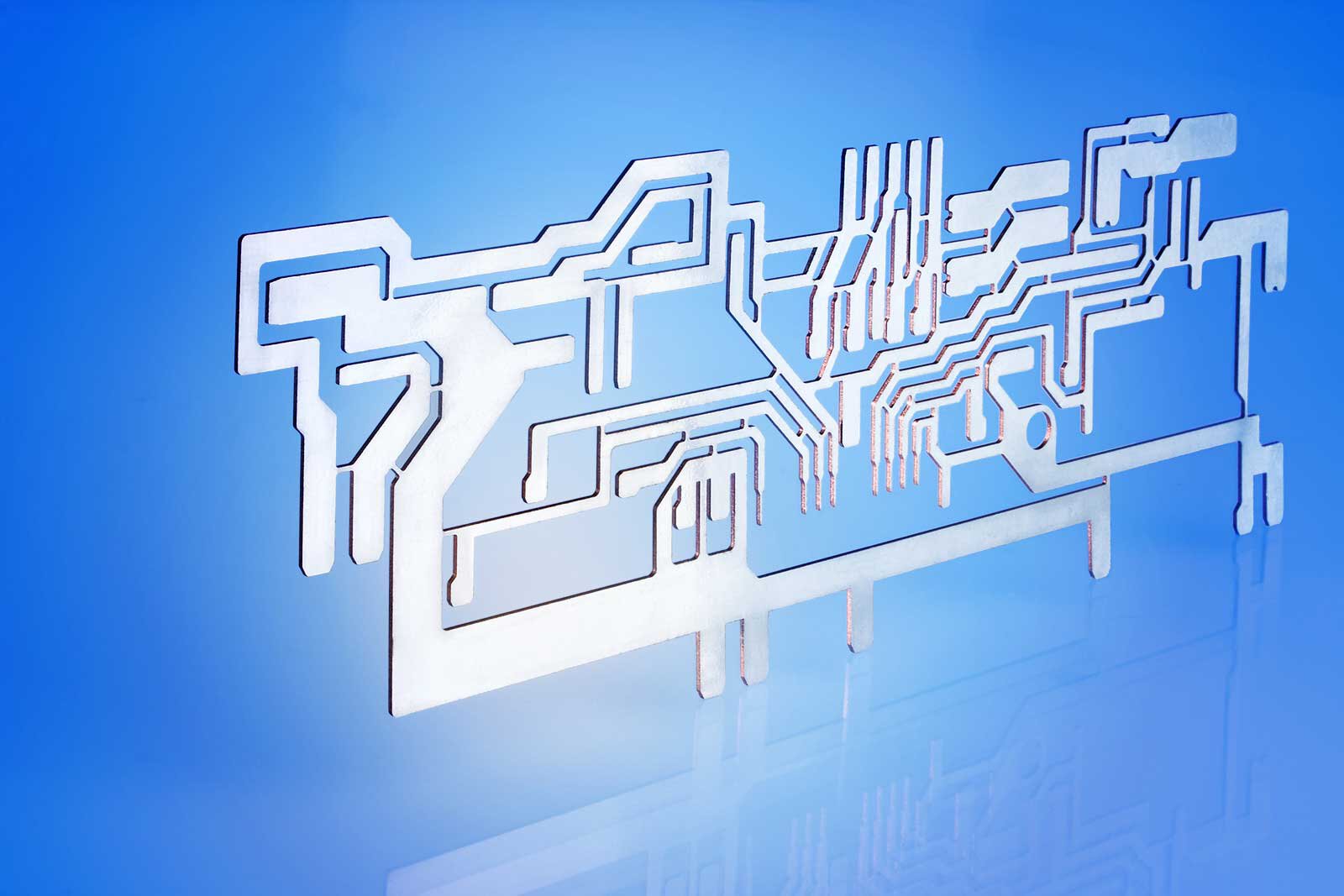

Busbars

Busbars are used in e-mobility applications to transmit high currents. Busbars up to a thickness of 5mm can be manufactured by stamping/bending.

One major advantage of this technology is its adaptability to various customer-specific connection requirements and the possible combination with plastic.

Your contact at iwis smart connect:

Marc-Michael Enzensperger, Head of Sales

Tel: +49 8362 9122-0