Tritan – the high-quality coating solution from iwis since 2008

Coatings for demanding applications in mass production

The innovative coating technologies offered by iwis upgrade your component while meeting the highest demands on wear resistance, corrosion protection, quality and appearance.

Robust surface finishing solutions for your individual applications are our inspiration. For many years, the automotive industry has been relying on our robust coating solutions which significantly improve wear protection for heavy-duty components. These precise and high-quality coatings improve wear resistance, offer corrosion protection and even a high aesthetic quality in a wide variety of applications - at reasonable market costs.

Our industry 4.0 process, which enables up to 100% component inspection and ensures clear traceability of all components, is specially designed for small components and large quantities. The handling of large quantities of components in bulk is one of our unique selling points, in addition to the actual coating competence. Please contact us for quantities of +50,000 or more.

iwis is your development partner when it comes to identifying new application possibilities. We offer cross-industry collaboration for the identification of new applications, including prototyping and individual process optimization.

Coating solutions for highest industry requirements

Our inspiration - product cost optimization / added value generation through:

- Scalability of the coating according to actual demand

- Functional property separation (e.g. inexpensive base material / high-strength wear and / or thermal protection layer)

- All-side - very high layer thickness homogeneity for rotationally symmetrical components (cylinders, balls, cuboids ...)

- functional interior coatings, undercuts and / or covered areas possible

- Material change: stainless steel, steel (high or low alloyed), aluminium, glass, ceramics etc. possible

Specifications

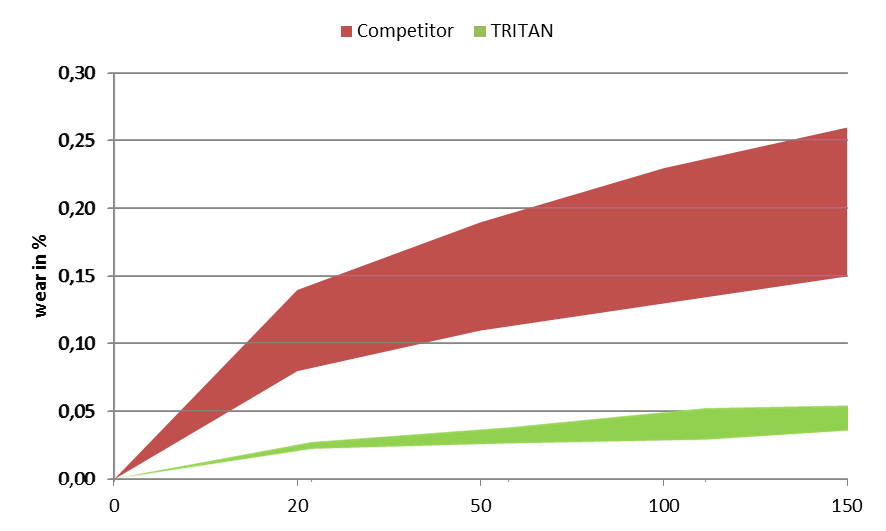

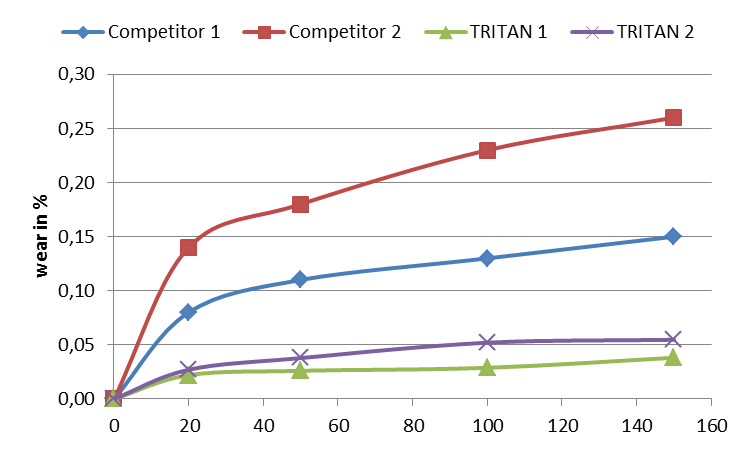

Wear performance of a Tritan coated Bush chain

Ask our coating expert

Your contact:

Dipl.-Ing. Berthold Kühnert

Director Fundamental Research

Phone. +49 8191 9155-3316

[email protected]