Sprockets and idler wheels for flat top chains

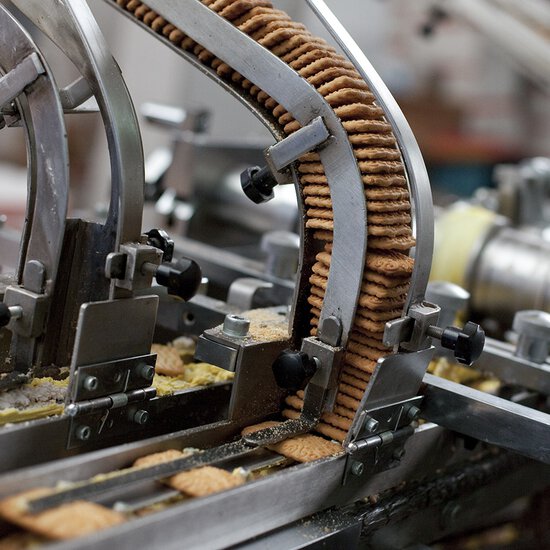

Sprockets and idler wheels for flat top chains are available in single-piece and split versions for the entire FLEXON range. In addition, iwis also manufactures sprockets and idler wheels made from plastic PA6, cast iron or steel ST52, depending on the application. Split plastic sprockets are the most commonly used version. The flat top chain used determines the sprocket design. Drive sprockets have a keyway for positive-locking power transmission, whereas idler wheels do not have a keyway. As an alternative, a deflection roller may be used instead of an idler wheel.

The advantage of split sprockets is that technicians do not have to remove the sprocket from the shaft to carry out maintenance work. The sprocket is simply split for removal and no other components are affected.

The forces in the sprocket that are exerted on the base of the tooth are much lower than those found in the sprockets used for roller chains. This is due to the sprocket width, which is in turn dependent on the flat top chain, so plastic is a suitable material here. Since plastic is more chemical-resistant, plastic sprockets are suitable for a wide variety of applications in different conditions.

Determines we will be glad to help you to choose the right chain and sprocket for your application. On request, we can also supply sprockets with push-fit ball bearings or taper-lock bushes.

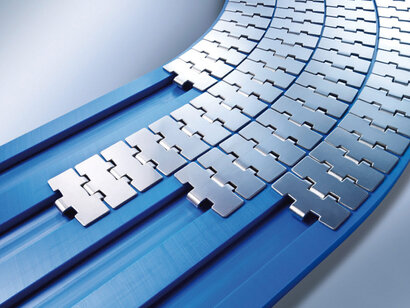

Guide rails, curves and magnet systems

FLEXON guide rails, curves and magnet systems are designed for compatibility with the entire product range. Manufactured from special materials, they offer a low coefficient of friction and high wear resistance in combination with FLEXON flat top chains. FLEXON magnet systems prevent the corresponding side-flexing flat top chains from rising or jumping off in curves.

Please see our catalogue for more information about FLEXON guide rails, curves and magnet systems.