Shorter delivery times for iwis accumulation chains

01. Feb 2023 | iwis drive systems

Investment in automation leads to more efficient production

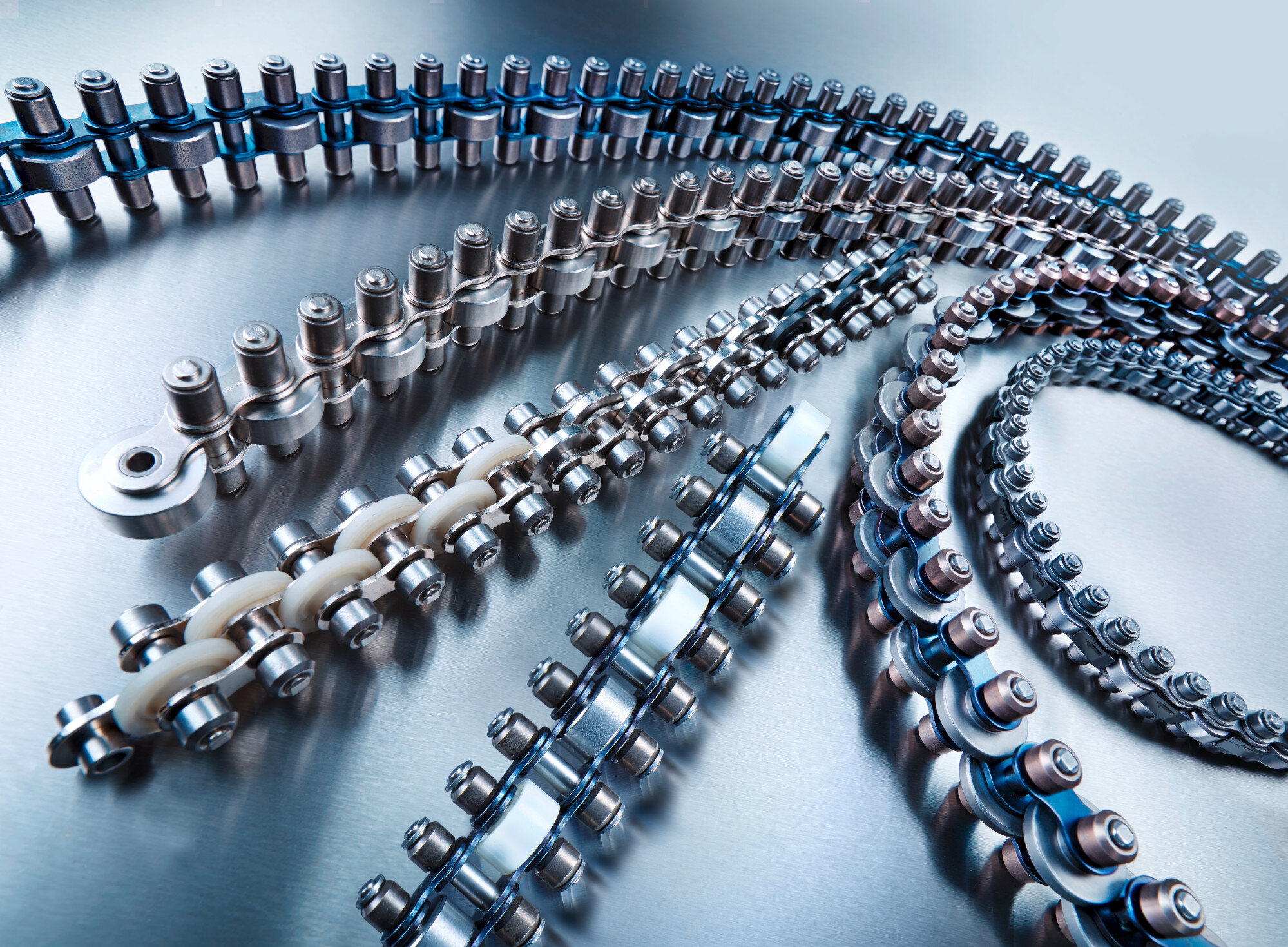

Munich, February 2023. No jolts or stopping: What applies to our own accumulation chains should also apply to their production. Shorter delivery times as a result of more efficient production was the explicit aim of the iwis Czech plant of iwis: iwis has invested massively in the automation of production in Strakonice over the recent months in order to further reduce manual operations. New automatic machines for inner and outer links were taken into operation for the production of JWIS-branded accumulation chains, and chain assembly was also further automated.

Accumulation chains: Rapid deployment for reliable production

iwis accumulation chains guarantee problem-free positioning of conveyed goods via simple stopping points and prevent jolts when the belt starts and stops. The normal speed of the chains is 0.1 to 0.5 m/s. By fitting a simple acceleration rail, the transport speed at locations in which material is not accumulated can be doubled without changing the chain speed. Thanks to a special wax lubricant applied to the articulated points, the chains remain clean and low-maintenance. This lubricant is applied directly to the individual parts prior to chain assembly. As a result, the transport rollers on which materials are conveyed remain grease-free. A special-purpose initial lubrication can be used for specialized applications. Accumulation rollers are available in the following materials: hardened steel, stainless steel, nickel-plated or plastic (including antistatic).

iwis is now able to offer faster delivery times, in particular for the following types of accumulation chains:

- ½“ accumulation chains of the types L85 SFK (with plastic accumulation rollers) and L85 SFS (with hardened steel accumulation rollers), construction: OS (standard version without washers)

- ¾“ accumulation chains of the types M127 SFK (with plastic accumulation rollers) and M127 SFS (with hardened steel accumulation rollers), construction: OS (standard version without washers)

- ½“ accumulation chains of the types L88 SFK-SB (with plastic accumulation rollers) and L88 SFS-SB (with hardened steel accumulation rollers), construction: side bow accumulation chains

- ¾“ accumulation chains of the types M 120 SFK-SB (with plastic accumulation rollers) and M 120 SFS-SB (with hardened steel accumulation rollers), construction: side bow accumulation chains

The JWIS L88SF and M120SF accumulation chains offer optimized load distribution and the offset arrangement of the accumulation rollers ensures better support and smoother running of the transported material. Offset accumulation rollers also reduce the load on the plastic guides by 50 percent: As a result, plastic guides can be used with up to twice the weight load..

New CNC machines save time

In addition, iwis has also invested in three new CNC lathes at the Strakonice plant in order to be able to produce ¾" plastic or steel accumulation rollers more efficiently with immediate effect. And this also results in significantly shorter delivery times. The raw material for a wide variety of accumulation rollers is mostly kept in stock. This means that custom accumulation roller types can also be produced at short notice.