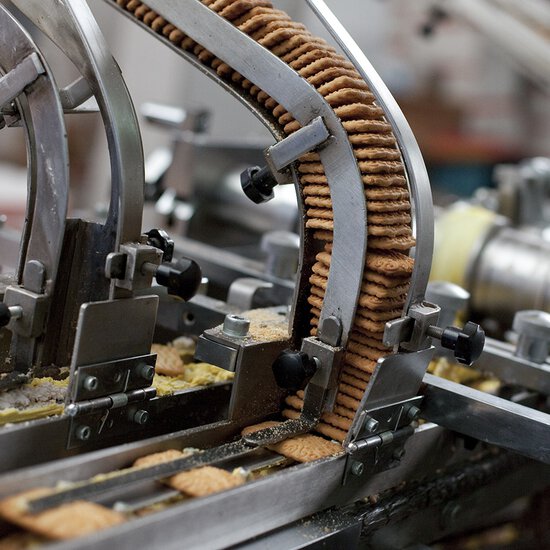

Pin Oven Chains

Cans and other thin-walled hollow containers need to be conveyed safely and reliably at high speeds and high temperatures. The pin oven chains (POC) developed by iwis offer a number of benefits: the precision roller chains are particularly wear resistant and treated with our special lubricant IPP before they leave the factory. IPP is PWIS-free, drip-proof, suitable for high-temperature applications and approved for use in the food industry.

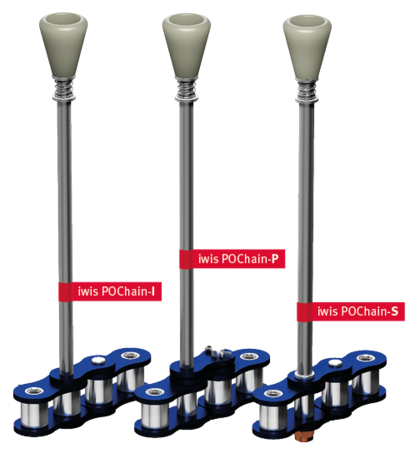

The transport pins are easy to change without breaking the chain or removing it from the machine. There are three fixture versions to choose from (pins integrated in the outer chain plates, pins fixed using special nuts and split-pin fixture). Users can also choose between two transport pin versions: flexible or snap-off. The flexible version can be bent back to its original position easily and by hand following an accidental impact resulting from a conveyor jam, for example. The advantage of the snap-off pin is that it will separate from the chain in the event of an accidental contact or impact during operation.

Two pin versions to cover all requirements

Bendable pin

These pins are manufactured to be tough yet bendable enough to withstand inadvertent impact during conveyor jams or accidental contact with the machine frame. These pins are easy to bend back into their original position by hand.

SnapOff pin

The material specification of these pins cause them to break off in the event of any accidental contact or impact during operation. The advantage for you: the hardness of the transport pin material is similar to that of the pins of the base chain, so the wear rate of both sets of pins is the same.

iwis Elastic Can Tip (ECT)

- Less complex design: one high-temperature elastomeric head replaces one PEEK protective head, three washers and a spring!

- The design and material properties of the elastomeric head take over the damping properties of a spring.

- Defective heads can be replaced easily and without tools.

- Even defective heads still have emergency running capabilities.

- ECT material is PWIS-free and FDA approved!

- Will not damage thin-walled drinks cans.

- Suitable for temperatures up to 215 °C. Available now!

Highlights

- iwis precision roller chains are long-lasting, reliable and particularly wear resistant

- iwis Pin Oven Chains for can manufacturing applications are initially treated with our special lubricant IPP. IPP is PWIS-free, drip-proof, has a very low evaporation rate, is suitable for

- high-temperature operation and approved for use in the food industry

- Standard protective head: high-performance material (PEEK), outstandingly heat-resistant (up to at least 260 °C, depending on application). PEEK is also highly resistant to chemicals. Protective heads are also optionally available with sliding washers, if necessary (only recommended for applications where contamination is uncritical).

- Length of transport pins can be adapted to your specifications.

- Transport pins: easy to change on the production line without breaking the chain or removing it from the machine (POChain P/-S)

- Transport pins can be installed at defined intervals (e.g. every 7th pin)

- iwis offers three fixture options for transport pins:

- POChain-I: pins are integrated in the outer chain plates

- POChain-P: split-pin fixture

- POChain-S: pins are secured with special nuts

- Temperature range: 0 °C to +260 °C

Further technical information can be found in our Pin Oven Chain product flyer.

Categories that may be of interest to you

Pin Oven Chains – a world of variety

iwis pin oven chains are based on JWIS precision roller chains with SL pins, so they are particularly durable, reliable and wear-resistant. The lubricant IPP was specially developed for the can-making industry and is ideal for the high temperatures involved. The length of the transport pins can be adapted to suit the requirements of individual applications. Three different fixture types ensure ideal conditions for all kinds of requirements. For example, predetermined breaking points prevent collisions during the passage of cans through the plant, and a quick-change system enables fast, easy replacement of pins without breaking the chain or removing it from the machine.

Protection heads in a variety of different materials and with different geometries ensure particularly gentle handling of the cans on the conveyor. Pin oven chains are particularly wear-resistant high-performance chains; they also feature specially adapted transport pins and high-quality protective heads – the right solution for every 2-piece can application!