Roller chain 24B-1, nickel-plated - ELITE

Part no.: Icb80f0331420

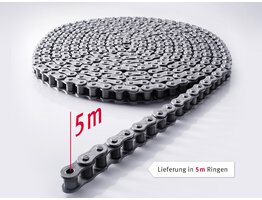

Packaging Unit:

5m

Brand:

ELITE

Surface:

nickel-plated

Corrosion-resistant

Resistant to water and air

Versatile

Note:

Please ask for the product directly. We manufacture according to customer requirements.

Please ask for the product directly. We manufacture according to customer requirements.

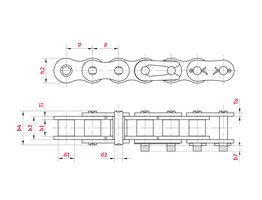

Technical data

Roller chain

24B

Pitch p (mm)

38,1

Width between inner plates b1 min. (mm)

25,4

Roller diameter d1 max. (mm)

25,4

Pin diameter d2 max. (mm)

14,63

Pin length b4 max. (mm)

53,4

Max. add. length of connecting link b7 max. (mm)

6,6

Plate thickness Ti/To (mm)

6,00/4,80

Height inner plate h2 max. (mm) (JWIS: g)

33,4

Min. tensile strength ISO/DIN FU (kN)

160

Weight per meter (kg)

7,1

Bearing surface f (cm²)

5,54

Product Information

Nickel-plated chains are used mainly in the food and packaging industry; the characteristic properties of nickel make it a particularly suitable coating metal for numerous applications. It is impervious not only to water and air, but also to a variety of acids and alkalis.

Product highlights

- The dimensions of all zinc-plated and nickel-plated ELITE-chains comply with the requirements of ISO 606 and the chains are interchangeable with standard chains

- Zinc-plated and nickel-plated chains are prestretched to 30 % of breaking load

- All chain plates are tapered and zinc or nickel plated

- Chains are fitted with seamless rollers; zinc or nickel plating available

- Pins offer a high level of corrosion protection and wear resistance

- The load capacity of zinc- or nickel-plated ELITE chains is similar to that of comparable standard chains

- Both chain types are generally supplied lightly oiled

Applications

- Food processing industry

- Packaging industry

- Solar and energy technology